What Is Plaster?

Important Point

This id the process of covering rough walls, uneven surfaces in the construction house and other structures with a plastic material, called plaster or mortar.

Sometimes, the term ‘rendering’ is used instead of plastering when the plaster or cement is applied to the external surface of the wall either to improve the appearance or to protect then from wether agencies, such as rain heat, etc.

Methods of Plastering

Plater is applied in the manner mention below. To get uniform 150 x 150 mm and 10 mm thick dots are prepared on the surface at a lower level.

Those dots are transferred on the upper level with a plumb bob, so the dots of the upper level and lower come in one and vertical surface.

In this, any dots are applied on all the surface of the wall at 1500 to 2000 mm. Four dots are covered masonry with the help or screed, and plaster is applied properly.

Lime plaster is applied in these coats or in three coats or in two cots. The background is prepared before applying plaster.

- Three Coat Plaster

- Application of Rendering Coat

- Application of Floating Coat

- Application of Finishing Coat

- Two Coat Plaster

- Cement Plaster and Cement Lime Plaster

- Two Coat Plaster

- Three Coat Plaster

- Single Coat Plaster

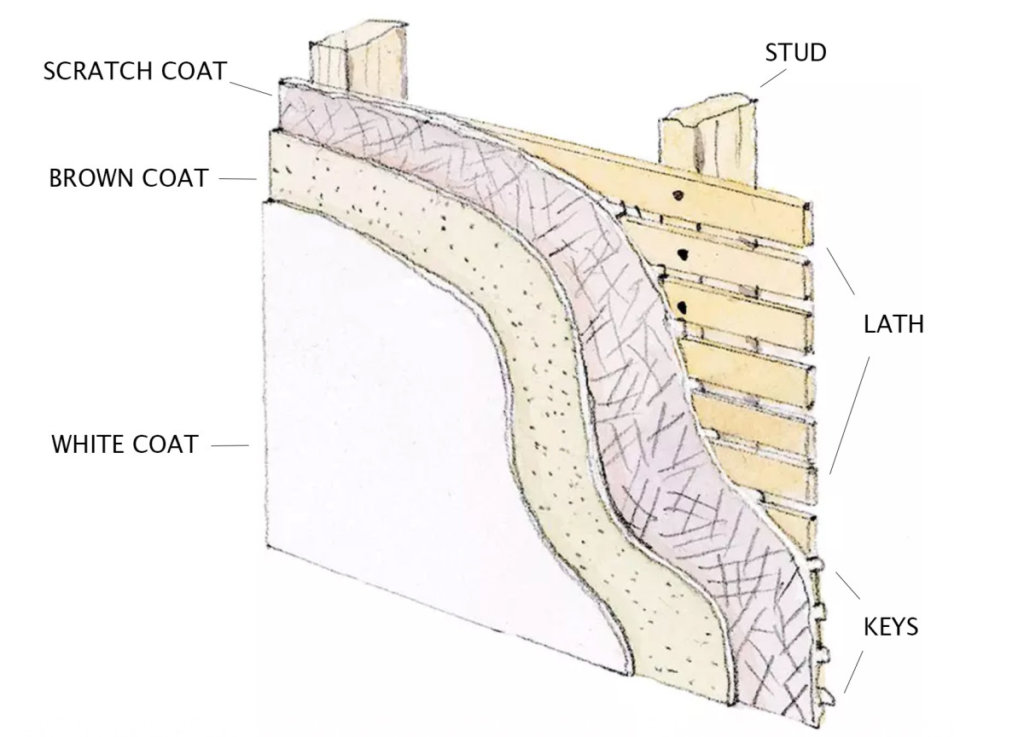

- Plaster on Lath

- Wooden Laths

- Metal Lath

Also, read: Curing In Construction | Concrete Cure Time | Methods of curing

1. Three Coat Plaster

The procedure of applying three-coat plaster is similar to two-coat plaster only difference is that an intermediate coat is known as a floating coat. The purpose of this coat is to bring the plaster to an even surface.

In the case of 3-coat plaster, the first coat is known id rendering coat, the second coat is known as a floating coat, and third coat is known as setting coat or finishing coat.

The rendering coat is applied, and scratches are made. The floating coat is applied, and after seven days finished coat is applied, after 6 hours of applying a floating coat.

1.a. Application of Rendering Coat

The mortar is applied forcibly on the surface of wall. With masons trowel and pressed well into joints and over the surface. The thickness of the coat should be such as to cover all inequalities of the surface normally this thickness is 12mm.

This coat is allowed to harden slightly a then scratch marks are made on the surface with the help of trowel ledge. During this period, the surface is curved and then allowed to dry completely.

1.b. Application of Floating Coat

The first coat is prepared properly to apply the second coat, i.e., a floating coat. All dirt and dust are cleared. It is wetted properly. 10 cm wide strips or 15 cm x 15 cm patches are applied at a suitable distance. These patches or strips act as a gauge for thickness or floating coat.

The mortar is dashed with mason’s trowel, spread, and rubbed to the required plain surface with a wooden float. The floating coat is beaten with floats edge at the close spacing of cm. Then it is allowed to dry completely. The thickness or floating coat is 6 to 9 mm.

1.c. Application of Finishing Coat

The third coat is called a finishing coat. In the Case of lime-sand mortar, the finishing coat is applied immediately after the floating coat cream of lime and sand in 4:1 are applied with a steel trowel and rubbed and finished smooth.

The rubbing is done till the finishing coat is quite dry. Then curing is done after one day for seven days.

Also, read: What Is Plaster | Type of Plaster | Defects In Plastering

2. Two Coat Plaster

The joints are ranked at a depth of 20 mm. The surface is cleaned, and water is sprinkled property on it.

- Before the first coat is applied preliminary coat is applied to make an uneven surface in le.

- Then, the first coat is applied. The first coat is racked as a rendering coat. The thickness first coat is kept 2 to 3 mm less than a total thickness of plaster.

To maintain interim thickness and vertically of plaster 15 cm * 15 cm dots or are provided, Then a vertical strip of mortar known as the spread is formed at a distance of 2 m. spacing.

Then the spaces between screeds are filled with mortar and properly finished.

- Scratches are made on rendering coat to provide mechanical key before it hardens. The rendering coat is watered for 2 days and then dried.

Before applying the final/coat, the rendering coat is damped well. The final coat is applied with wooden floats to a true even surface with steel trowels. The thickness of the final coat may vary from 2 to 3 mm.

3. Single Coat Plaster

This is used only in interior quality work. It is applied similar to two coat plaster except that the rendering coat as applied fro two-coat plaster is finishing off immediately after it has sufficiently hardened.

Also, read: Difference Between Bitumen and Tar | What Is Bitumen | What Is Tar

4. Cement Plaster and Cement Lime Plaster

For interior work single coat plaster is applied. For good quality works, either two coat or three coat plaster is applied. But two coat plaster is more common sow shall discuss it first.

5. Plaster on Lath

Thin partition walls and ceilings are plastered using laths. Laths are provided as a foundation to receive plasterwork. Laths may be.

- Wooden laths

- Metal laths

5.a. Wooden Laths

Wooden laths are well seasonal wooden strips 25 mm wide and 1 to 1.2 m long. Wooden laths are used and ceilings.

Laths are fixed in a parallel line with a clear spacing of 10 mm and secured to the surface with galvanized iron nails.

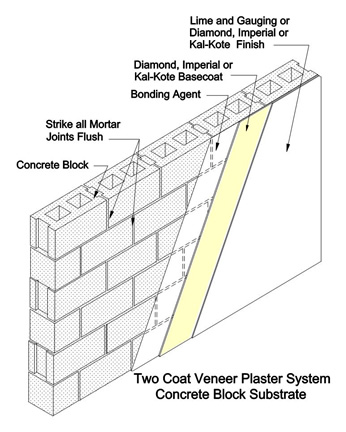

5.b. Metal Laths

Metal laths are available under various patent names. The plain expanded metal lath(exam) is commonly metal laths are fixed to the surface by G.I Staples.

In the case of concrete or masonry surfaces, wooden plugs have to be embedded for fixing the lath. After fixing the lath, the surface is plastered, usually, in there coats, cement mortar is used.

What Is Plastering in Construction?

Plastering is the process of covering rough walls and uneven surfaces in the construction of houses and other structures with a plastic material, called plaster, which is a mixture of lime or cement concrete and sand along with the required quantity of water.

Like this post? Share it with your friends!

Suggested Read –

- West Point Bridge Designer

- Difference Between CPM and PERT | What Is CPM & PERT

- Difference Between One Way Slab and Two Way Slab | What is Slab

- Introduction of USCS | USCS Classifies Soils into Two Broad Categories

- Introduction of Gantry Girder | Load on Gantry Gutter | Type of Load on Gantry Gutter

- What Is Pier Foundation | Types of Drilled Piers | Advantages and Disadvantages of Drilled Pier Foundations

Professional plasterers look after the cleaning of the mess and do not spoil the objects around the place. A local plasterer will not pay heed to you and your place safety. In plastering dangerous types of equipment are used.

thanks for sharing the information

Interesting! It is of great help to me.