Introduction of PRE Engg Building

Important Point

The Steel industry is growing rapidly all over the world. Steel is widely used Building material in the construction industry.

Nowadays steel structures getting more popularity because of its economy and faster construction.

The owner of the example of steel structure is PEB building.

In this article, you will get to know about pre-engineered buildings, its components, advantages and disadvantages.

The PEB full form is Pre-Engineered Buildings. The Buildings which are Engineered at the factory and assembled at the site are known as pre-engineered buildings.

The pre-engineered buildings are widely used for the construction of industrial buildings and warehouses metro stations factories and bridges etc.

PEB buildings are the steel structures which are fabricated at the factory to the required size and dimensions. Pre-engineered buildings at transport it an assembled at site with bolted connections.

Pre-engineered buildings are steel structures from which the structure members are constructed like columns, roof truss, purlins etc.

Pre-engineered steel buildings are constructed using Steel built-up sections that are designed and fabricated in the factory and assembled at the site by using various bolted connections.

The Pre Engineered Structure have more advantages as compared to conventional Steel buildings.

PEB shed mostly used in the construction of industrial buildings.

PEB construction is economical and easier in fabrication.

PEB structure can be finished internally to serve the functions which are required in the design of low rise building.

Components of Pre Engineered Buildings

The pre-engineered building is constructed with different components and connections.

Pre-engineered buildings consist of difference structural Steel members which are as follows

1. Primary Frame

The Primary frame which is used in PEB construction is an assembly of built-up sections which forms framing and consists of trusses or castellated beam.

2. Secondary Structural Elements

The secondary structural elements are cold-formed members in the different shapes such as Z and C etc.

3. Roof and Wall Panels

The tin Shades and curtain wall made up of Glass and rolled formed Steel is generally used in roof and wall panels.

4. Sandwich Panels

Sandwich panels are made up of three layers in which an all-aluminum core is inserted between two aluminum sheets.

- Queen Bed Dimensions in Feet

- Different Types of Cranes

- Zero Force Member Rules

- Wall Loading Calculations

- Shower Pan Cement

- Concrete Bags Per Yard

- Different Types of Shovels

- Dry Pack Mortar

- How Many Stairs in a Flight

- How to Find the Contour Interval

- Plywood Strength Psi

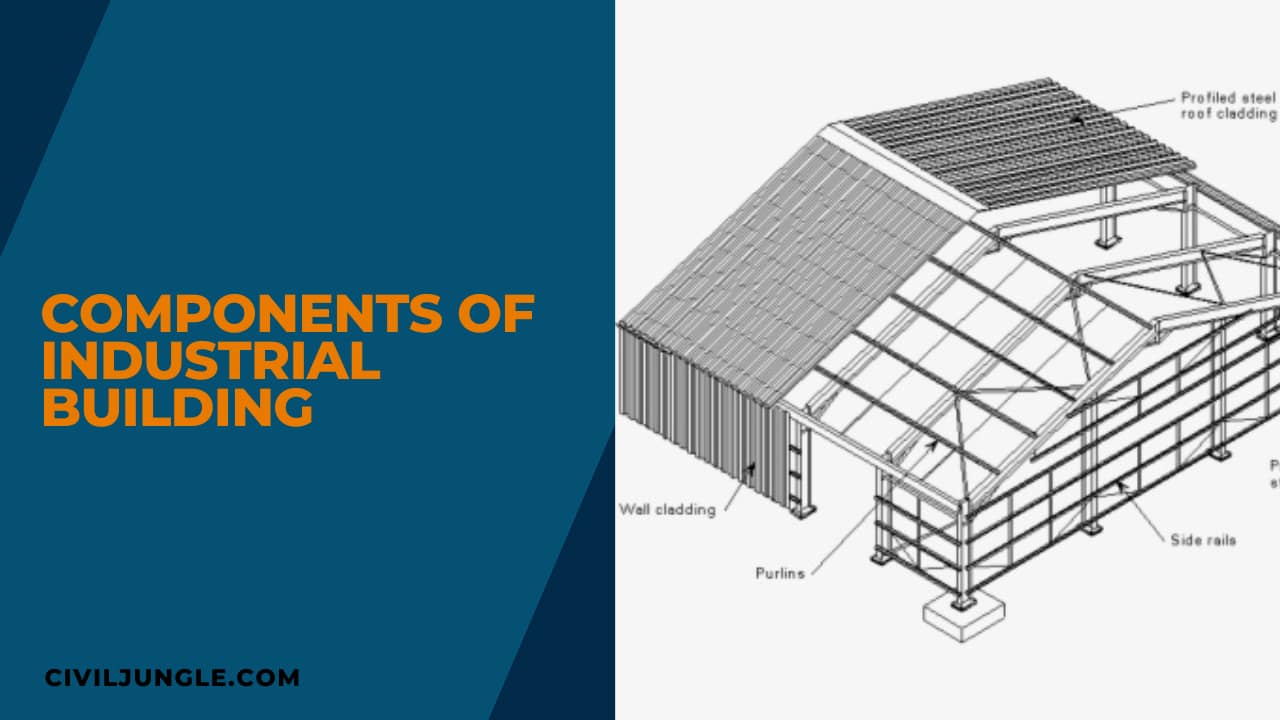

Components of Industrial Building

The different components of industrial buildings are as follows.

- Purlins

- Sag rods

- Principal Rafters

- Roof Truss

- Gantry Girders

- Bracket

- Column and Column base

- Girt Rods

- Bracings

Advantages of Pre-Engineered Buildings

The various advantages of Pre-engineered building are as follows

1. Quality control of construction:

In the case of the pre-engineered building construction, all the structural members are made in the factory under the supervision of quality control engineer.

2. Economy

The construction of a Pre-engineered building is less expensive as compared to another type of buildings.

Pre-engineered buildings save designing and manufacturing cost.

3. Less Maintenance:

The maintenance cost which is required for the pre-engineered building is very less as compared to the conventional steel buildings because of the use of high-quality paint.

4. Time Required for PEB Construction

The time required for pre-engineered buildings construction is less due to the design of the structural components using advanced software.

5. Warranty Period of Pre Engineered

The warranty period of Pre-engineered building is 20 years given by the manufacturers.

6. Erection of Pre-Engineered Building

The erection of Pre-engineered building components is very fast and easy due to the use of Pre-manufactured and skilled labour in pre-engineered building construction.

Disadvantages of Pre Engineered Buildings

There are also some disadvantages of Pre-engineered buildings which are as follows.

- This type of structure can be attractive when it is left exposed.

- The parts of the pre-engineered buildings are susceptible to corrosion.

- The insulating of the building will furthermore increase the construction cost.

Use of Pre Structure

The Pre-Engineered buildings are used for the following structures.

- For the Construction of Low Rise Industrial Buildings.

- Power Plants

- Warehouses

- Laboratories

- Airport Hangers

- Parking Lots

- Factories

How Pre Engineered Building Is Better Than Conventional Building?

Pre-engineered metal buildings have efficient design due to its integral framing system whereas the conventional Steel buildings have a less precise design which requires more time.

Pre-engineered Steel buildings are 10 to 20% lighter than conventional buildings.

PEB Construction and erection is faster and simple as compared to conventional Steel buildings.

PEB Buildings required light equipment for construction, and conventional building required more labour and heavy equipment for Construction.

Pre-engineered buildings have good resistance against systemic actions due to lightweight structure whereas conventional buildings cannot stand against systemic forces because of heavy structure.

Applications of Pre Engineered Buildings

- Warehouses

- Factories

- Workshops

- Offices

- Gas Stations

- Vehicle Parking Sheds

- Showrooms

- Aircraft Hangars

- Metro Stations

- Schools

- Recreational

- Indoor Stadium Roofs

- Outdoor Stadium Canopies

- Bridges

- Railway Platform Shelters

Pre Engineered Building Design Calculations

The pre-engineered building design calculations are done by the main framing of the engineered Building System by the Stiffness Matrix method.

The design of the pre-engineered building is based on the allowable stress design as per the American Institute of Steel construction specification.

The design cycle consists of the following steps.

- First upon set up the section of the required size and breast locations based on the geometry and loading.

- Then calculate the shear moment and axial force at each point for each load combination.

- Identify and compute allowable share stress and allowable bending stress in the compression and tension at each analysis point.

- Calculate the corresponding stress ratio for shear and axial and bending based on the allowable stresses.

- Design the optimum location and check whether the predicted size is as per the manufacturing constraints or not.

- At the end of the design process, the analysis of the structure is done for further optimization.

Also Read: Ferrocement Structure

Load Calculations for Pre-Engineered Buildings

The load calculations for pre-engineered buildings is that load considered are the same as for general building structure.

- Dead Load Calculations: The dead load includes self-weight of purlin, roof and wall sheeting and other structural components.

- Live or Imposed Load Calculations: This type of load should be considered as per IS 875 (Part 2)

- Wind Load Calculations: Considered the basic wind speed as per the space of the structure. The wind pressure is calculated as per the IS 875 (Part 3)

- Seismic Load Calculations: Earthquake loads can affect the whole structure so that it is necessary to consider it during the designing.

- Load Combinations: As per IS 1893 2002 (Part 1), 7(DL ± LL), 7(DL ± EL) , and 3(DL + LL ± EL)

Peb Structure

Pre Engineered Buildings (PEB) are the buildings which are engineered at a factory and assembled at site. Usually PEBs are steel structures.

Built-up sections are fabricated at the factory to the exact size, transported to site and assembled at site with bolted connections.

Peb Shed

In structural engineering, a pre-engineered building (PEB) is designed by a PEB supplier or PEB manufacturer, to be fabricated using a best suited inventory of raw materials available from all sources and manufacturing methods that can efficiently satisfy a wide range of structural and aesthetic design requirements.

Peb Full Form

In structural engineering, a pre-engineered building (PEB) is designed by a PEB supplier or PEB manufacturer with a single design to be fabricated using various materials and methods to satisfy a wide range of structural and aesthetic design requirements.

Components of Industrial Building

- The primary steel frame consists of columns, rafters and bracing. The example shown is a portal frame. However, it is equally applicable to other types of structural frames.

- The secondary steelwork consists of side rails and purlins for the walls and roof respectively. These members serve three purposes:

- To support the envelope.

- To transfer load from the envelope to the primary steel frame

- To restrain the primary steel frame members

- The roof and wall cladding, whose functions include some or all of the following:

- Separating the enclosed space from the external environment

- Transferring load to the secondary steelwork

- Restraining the secondary steelwork

- Providing thermal insulation

- Providing acoustic insulation

- Preventing fire spread

- Providing an airtight envelope

- Providing ventilation to a building (ventilated or unventilated roofs and walls).

What Is a Pre Engineered Metal Building?

More than just four walls and a roof, a PEMB is a structure that is built using a structural steel framing system specifically engineered to fit your project requirements. All of the predetermined components of the structure are fabricated off-site under precise factory conditions.

What Is Conventional Building?

Conventional buildings on the other hand are traditional buildings consisting of steel, brick and cement sections. These are fabricated and assembled at the site. Conventional building method involves welding and cutting, which is done largely at the construction sites.

Pre Engineered Buildings Vs Conventional Buildings

Pre-engineered steel buildings use pre-fabricated pieces that are transported to the site, whereas conventional construction uses diverse materials (typically concrete, masonry, or wood, with some steel structures) that are created onsite.

Advantages of Pre Engineered Steel Buildings

Advantages of Pre-Engineered Steel Building

- Time-Saving. While construction cycles of standard structures take a longer time to complete, pre-engineered structures take fewer months or weeks.

- Cost-Saving.

- Low-maintenance.

- Weather Resistant.

- Energy Efficient.

- Durable.

- Customizable.

Peb Building

A PEB (Pre-Engineered Building) is a type of building construction that involves the use of pre-fabricated and pre-designed components. These components are manufactured off-site and then assembled on-site to create a complete building structure. PEBs are known for their efficiency, cost-effectiveness, and speed of construction. They are widely used in commercial, industrial, and residential applications.

Peb Structure Meaning

Pre-Engineered Buildings (PEBs) are the building components that are manufactured at a factory and assembled on site. Usually, PEBs are steel structures and can be an alternative to conventional structural steel buildings.

The Disadvantage of the Peb Is

If not properly maintained it can be susceptible to corrosion. Steel, although a good conducting metal, reduces the thermal comfort of the building. This type of building becomes more susceptible to fire and damage due to its conductivity.

Pre Engineered Building Components

Components of Pre-Engineered Steel Buildings

- Primary Components: Primary Components consist of mainframes, columns, and rafters.

- Secondary Components: Purlins, girts, eave struts, and bracings make up the secondary components of pre-engineered buildings.

- Cladding or Sheeting.

- Accessories.

Types of Peb Structures

- Rigid Frames: Rigid Frames are structural skeletal members bearing the load of the entire building.

- End Wall Frames.

- Wind Bracing.

- Crane Brackets.

- Roof Purlin.

- Wall Girts.

- Eave struts.

- Sag Rods.

Pre Engineered Buildings Advantages and Disadvantages

Advantages of Pre-Engineered Buildings (PEBs):

- Faster Construction

- Cost-Effective

- Customization and Flexibility

- Structural Strength and Durability

- Energy Efficiency

Disadvantages of Pre-Engineered Buildings (PEBs):

- Design Limitations

- Site Limitations

- Transportation and Logistics

- Dependence on Manufacturer

- Local Building Codes and Regulations

Pre Engineered Steel Buildings

Pre-Engineered Steel Buildings (PESBs) are a type of Pre-Engineered Building (PEB) that specifically utilize steel as the primary material for construction. PESBs are designed, manufactured, and assembled using pre-fabricated steel components, resulting in efficient and cost-effective building construction. Steel is a versatile and durable material that offers numerous advantages in building construction, making PESBs popular in various commercial, industrial, and residential applications.

Engineered Structure

Engineered Structure means any structure or facility designed and approved by a Professional Engineer.

Conventional Steel Building

Conventional steel buildings are traditional metal structures constructed by rolled steel sections which are designed individually and fabricated at site using welding and cutting.

Like this post? Share it with your friends!

Suggested Read –

- Difference Between Marble and Granite | What Is Marble and How Is It Made | What Is Granite and How Is It Made

- What Are Walls | What Is Interior Walls | Types of Interior Wall Materials | Types of Wall Construction | Types of Load Bearing Wall

- Building Layout | How to Building Layout | What Is Method of Layout of Building | Control Lines of Construction | Construction Layout

- Emulsion Paint Vs Oil Based Paint | Purpose of Providing Paints | Properties of Good Paint | Properties of Good Paint | What Is Oil Based Paint

- Difference Between Sketching and Drawing | What Are Conceptual Sketches | Architecture Concept Drawing | Types of Drawings for Building Design

- Definition of Shear Force and Bending Moment | What Is Shear Force | What Is Bending Moment | Relation Between Loading, Shear Force & Bending Moment

Good explanation of PEB components and advantages.

Very informative post. Thank you. The usage PEB should highly be encouraged.