What Is Recycled Concrete Aggregate?

Important Point

Recycled concrete aggregates (RAC concrete), a form of crushed concrete aggregate, are an alternative to the use in concrete and aggregate of natural aggregates (NA).

Recycled concrete aggregates ( RCA ) are aggregates produced by clean concrete waste that must contain very low amounts of other building waste – less than a few percent.

Crushed gravel, recesses, retention walls, landscape gravel, or staple for the branding of new concrete is frequently used. The giant items are often used as bricks or slabs or built into structures with new concrete, a so-called urban tissue.

In the early stages, concrete foundations, sidewalks, drives, and various structures of concrete are broken down, which may traumatize a contractor with a large volume of dense, serious materials.

Often in many ways, can concrete be recycled and reused, highlighting the importance of what is recycled aggregate concrete. The method usually involves (but not always) the crushing of concrete waste close to demolition or vacancy.

The most effective technique is usually based on the size and the shape of the concrete items to be recycled. The use of recycled aggregates is undoubtedly an essential step towards sustainable development in the concrete industry and building waste management.

Recycled aggregates ( RA ) are a feasible alternative to natural aggregates that contribute to environmental preservation. Variability of aggregation characteristics is one of the major parameters affecting the utilization of recycled aggregates.

The grade of the recovered aggregate, often considered in aggregate prices per ton, depends on the quality of the materials collected by the recycling plants and delivered there.

The manufacture of recycled aggregates is therefore difficult to achieve at an acceptable price and quality, due to the present restriction on the recycling systems.

Also, Read: Top 15+ Best Plywood Brands in India

Useful Article For You

- What Is a Contour Interval

- What Is Tile

- What Is the Difference Between a Shower Pan and a Shower Base?

- What Is a Window Panel

- Type of Arch

- What Is the Measurement for a Queen Size Bed

- What Is Considered Livable Space

- What Is One Way You Can Save Electricity?

- What Is a Bundle of Shingles

- What Is a Gallon of Water Weigh

- What Is Sand Blasting

- What Is a Span Bridge

- What Is the Little Black Diamond on a Tape Measure

- What Is a Louvered Door

- What Is a Spread Footing

- What Is Leveling

- Different Types of Beam

- What Is Pedestal

- What Is Plumbing Fixtures

- Soft Floors

- What Is Slab Construction

- What Is Calacatta Quartz

- What Is Auxiliary View

- Sheepsfoot Roller

- What Is 1 Flight of Stairs

- What Is Refractory Cement

- Dry Pack Concrete

- What Is Luminous Flux Vs Lumens

- What Is a Frost Wall

- What Is an Undercoat

- What Is Road Pavement

- Arch Foundation

- What Is a Stair Landing

- What Is a Spandrel Beam

- What Is Pier and Beam Foundation

- What Is a Pile Cap

- What Is a Mat Foundation

- What Is a Floating Slab

- What Is the Purpose of Foundation

- What Is a Flush Door

- What Is Residential Construction

- What Is the Best Foundation for a House

- What Is a Benchmark in Surveying

- What Is a Engineering Drawing

- What Is an Admixture

- What Is the Standard Size Water Supply Line

- What Is the Difference Between Tension and Compression?

- What Is a Tremie

- What Is Tributary Area

- What Is Shoring Construction

- What Is a Cason

- What Is Wall Putty

- What Is the Difference Between Mortar and Concrete

- What Is Bhk

- What Is Sbc of Soil

- What Is Plinth Level

- What Is Water Proofing

- What Is Mix Design of Concrete

- What Is Fine Aggregate

- What Is Retention Money

- What Is Design Mix

- What Is Isometric Scale

- What Is Development Length

- What Is Superelevation

- What Is Wall Made Of

- What Is Micro Piling

- What Is Soil Stack

- What Is a Half Wall Called

- What Is Flagstone

- What Is a Cinder Block

- What Is Floors

- What Is a Parapet in Construction

- What Is Concept Drawing

- What Is a 30 Degree Angle

- What Is a Mezzanine Level

- What Is Plinth Area

- What Is Precipitation

- What Is a Soffit

- What Is the Difference Between Residual and Transported Soil

- What Is a Drop Manhole

- What Is Oblique View

- What Is a Flyover Bridge

- What Is Tie Beam

- What Is the Cost of 1 Bag Cement

- What Is Well Foundation

- What Is the Principle of Chain Surveying

- What Is Dlc in Road Construction

- What Are the Advantages of Levelling

- What Is Hardened Concrete

- What Is Plinth Protection

- What Is Wbm Road

- What Is Measurement Book

- What Is Traversing in Surveying

- What Is the Space Between Windows Called

- What Is a Moment Frame

- What Is 53 Grade Cement

- What Is True Slump

- What Is Joisted Masonry Construction

- What Is the Back Azimuth of 180 Degrees

- What Is Stretcher Bond

- What Is Consistency of Cement

- What Is Pointing

- What Is Design Period

- What Is Long Column and Short Column

- What Is the Full Form of Rcc

Importance of Recycled Concrete Aggregate

- Construction and demolition ( C&D ) trash is a significant part of the solid waste stream, accounting for around 25 % of total solid waste in the United States.

- Concrete makes up the majority of C&D material, accounting for over 70 % of all C&D-generated material before recycling.

- Recycling concrete instead of dumping or burying it in a landfill has a number of environmental and economic advantages. Among the benefits are: Reduced tipping fees and associated freight costs.

- Newly mined aggregate is more expensive. Concrete trash necessitates less landfill space.

- Gravel mining is reduced when recycled material is used as gravel.

- High-grade aggregate for road building is increasingly only available across longer distances, raising the associated economic and environmental costs of longer hauling routes against recycled material.

- Using recycled aggregates, known for their recycled concrete prices, instead of virgin materials saves money because they are less expensive to manufacture.

- If recycled materials are available locally, the cost of transporting aggregates can be reduced. Recycling aggregate for resale is less expensive than shipping unwanted materials to the landfill and paying the landfill tax.

- Recycled aggregate is considered a “green” construction material since it minimizes the amount of virgin aggregates produced and hence reduces the use of natural resources.

- In order to fulfill UK and sustainability targets, there is a rising demand on landfill capacity and on construction sites to divert trash away from disposal.

- Recycled aggregates can be utilized for a variety of purposes, including construction projects, landscaping, and home improvement projects.

- Studies show that recycled aggregate is just as structurally sound as natural aggregate and is just as safe to work with.

Also, Read: MDF vs Plywood | What Is MDF | What Is Plywood

Advantages of Recycled Concrete Aggregate

- It minimizes the amount of CO2 in the atmosphere because a big amount of carbon dioxide is absorbed while crushing into smaller particles.

- It expands the recycling industry’s employment options.

- According to a few research findings, using Recycled Aggregate Concrete reduces building costs.

- It is recognized as a ‘green’ building material.

- When recycled aggregate is employed, the amount of virgin aggregates produced is reduced, resulting in less usage of natural resources.

- Recycled aggregate concrete, suitable for a concrete aggregate driveway and using crushed concrete for driveway, can be used in a variety of applications. It can be used in a variety of construction tasks, landscaping, and home renovation projects.

- As a natural aggregate, it is dependable and safe to use.

- Reduces the demand for additional landfills by conserving landfill space.

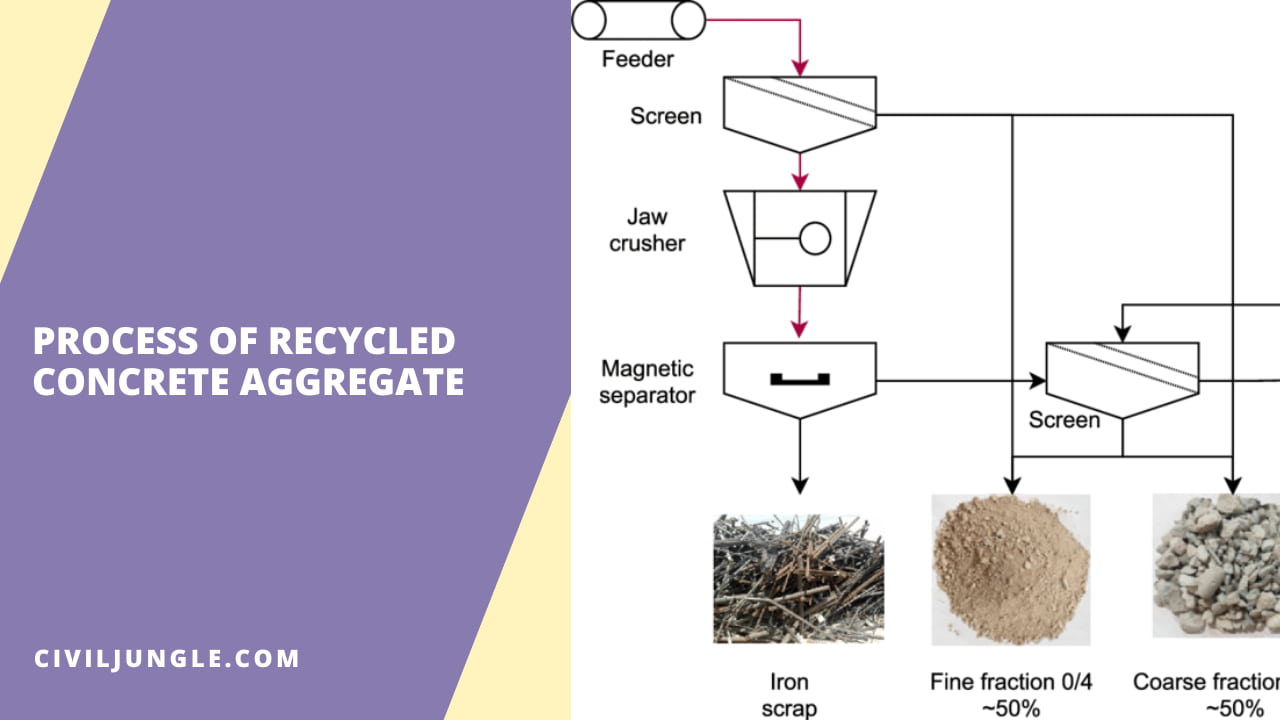

Process of Recycled Concrete Aggregate

- Urbanite (concrete debris objects) repurposing entails selecting and transporting the pieces before using them as slabs or bricks.

- The things are frequently shaped, for example, with a chisel; this may be time-consuming.

- Crushing entails eliminating waste, wood, and paper; extracting metals such as rebar, exploitation magnets, and alternative devices to be recycled separately; sorting the mixture by size; crushing it with a crushing machine; and removing alternative particulates by hand-picking and water flotation.

- Crushing at the development site using mobile crushers, a method of crushed concrete for driveway, is less expensive and environmentally friendly than carrying material to and from a quarry.

- Concrete and asphalt waste will be crushed at 600 tonnes per hour by massive road-portable facilities.

- A facet discharge conveyor, a screening plant, and a come-back conveyor from the screen back to the device for re-crushing large chunks are standard components of these systems.

- Compact, self-contained crushers can process up to 150 tones per hour and fit into tighter spaces.

- Crushing devices attached to construction equipment such as excavators can crush up to a hundred tonnes per hour, making crushing of smaller quantities more cost-effective.

- Aside from the foundation, RCA is a high-quality combination of several process steps such as crushing, pre-sizing, sorting, screening, and contamination removal. The idea is to start with clean material that can be sized according to product requirements.

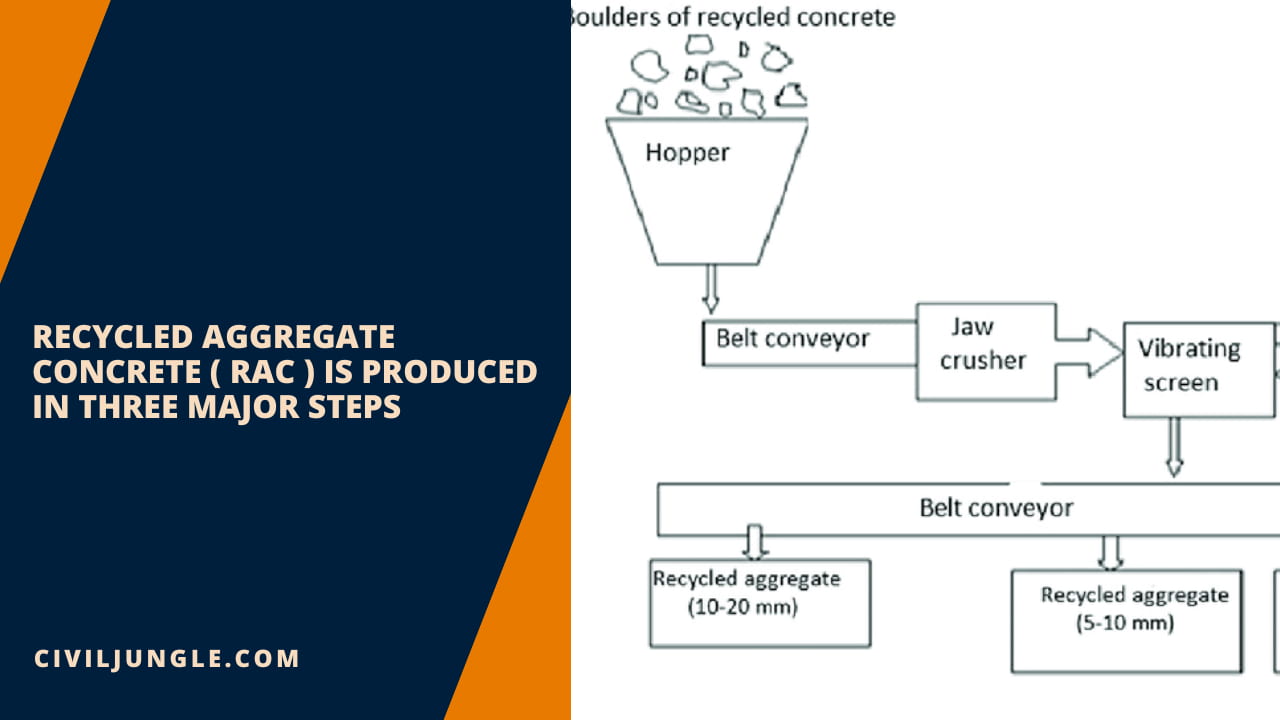

Recycled Aggregate Concrete ( RAC ) Is Produced in Three Major Steps

- The quality of the source concrete is determined first in the creation of RAC.

- For determining the right source concrete, properties and records of source concrete such as strength, durability, and composition are examined.

- Crushing concrete into desired size and quality ( typically 20 mm – 50 mm ) is a simple procedure.

- Reinforcing steel, foundation components, asphalt concrete shoulders, soil, and other contaminants are removed.

- Many ways can be used to accomplish this, including screening or air separation, demolition, and the use of electromagnets, among others.

- Some pollutants can be handled individually depending on how RCA is used.

Useful Article for You

- Zero Force Members

- How Much Does a Yard of Concrete Weigh

- Cmu Wall Meaning

- Gradient Road

- Budget Sunroom Ideas

- What Is Gypsum Board

- Types of Vaulted Ceilings

- How Does Baking Soda Remove Blood from Carpet

- What Are Forms in Construction

- How Heavy Is Dirt

- Tender Meaning in Architecture

- Dark Olive Green House

- Cast in Place Concrete

- Lean to Roof

- How Tall Is an Average Door

- Grade Beam Foundation

- Window Sill Height

- Concrete Cold Joint

- Types of Traps

- Types of Pipe

- Wood Supporting Beams

- Finishing Plaster

- Home Depot Scrap Wood

- Lvl Beam Size Calculator

- Structural Shell

- Curb Types

- Msand

- Optimum Dry Meaning

- Disadvantages of Low-E Glass

- Bridge Abutment Definition

- Build Materials List

- Composite Masonry Wall

- Is Cedar a Hardwood or Softwood

- Modified Proctor Test

- Physical Properties of Sand

- Crane Machine Construction

- Types of Gable Roofs

- Door Frame Types

- How Much Does 55 Gallons of Oil Weigh

- Dog Leg Stairs

- Concrete Salt Finish

- Westpoint Bridge Builders

- Types of Porches

- Hempcrete Disadvantages

- Roof Pitch Types

- Types of Weirs

- Asphalt Floor

- Dutch Roof

- #6 Rebar Weight Per Foot

- Prizmatic Compass

- Bond Break Concrete

- Poured Concrete Wall Cost Calculator

- How Many 60 Lb Bags of Concrete in a Yard

- Wood Fence Post Spacing Chart

- Falsework

- Design of Building Structures

- Topping Slab

- Types of Cinder Blocks

- Fresh Concrete

- Door Colors for Red Brick House

- Clear Cover Concrete

- Tiles Brand

- Cement Consumption in Plaster

- Aggregate Density Kg M3

- Weight of Concrete Slab Calculator

- Is Clay Smaller Than Silt

- How to Calculate Dead Load

- Bad Concrete Work

- Stepped Foundations

- Residential Construction Cost Estimator Excel

- Different Construction Trucks

- Septic Pump Replacement Cost

- Dead Load Calculator

- Beam Vs Column

- Concrete Mix Ratio

- Caisson Foundation

- Glulam Beam Weight Calculator

- Bituminous Pavement

- M30 Mix Ratio

- Is 2502

- Reinforced Brick Work

- Plinth Level

- Trapezoidal Footing Formula

- Slab Steel Calculation

- Rolling Margin of Steel

- Top 20 Pvc Pipe Brands in India

- Top 5 Cement in India

- How Much Weight Can a 6×6 Support Horizontally

- Modulus of Rupture Formula

- Types of Curtains

- Building Estimate Excel Sheet

- How Is the Skeleton Similar to the Frame of a House?

- Which of the Following Best Explains Why Buildings Tip During Earthquakes?

- Rate Analysis of Civil Works

- Water Tank Company Name

- 1 Soot in Mm

- Reinforcement Lap Length Table

- Camber in Road

- Rate Analysis of Plaster

Use of Recycled Aggregates In Construction

- Can be used to build gutters, pavements, and other structures, considering the recycled concrete cost and recycled gravel driveway benefits.

- Large pieces of crushed aggregate can be used to construct revetments, which are effective at preventing soil erosion.

- Concrete rubbles that have been recycled can be used as coarse aggregate.

- The production of RAC results in the production of a variety of by-products, including a ground improvement material, a concrete addition, and an asphalt filler, among others.

- As a base for road, parking and driveways, recycled concrete for driveway is a popular choice, and rear-filling material and shoulder stone, recycled aggregated concrete is used.

- Concerning 2″-4″ recycled stones also recycled concrete may be used. Typically this product is used for site stabilization, road base, and retro fill 3 on the lower layer.

- The square measurement of the small particles used as gravel for the brand new building.

- Sub-base gravel is arranged as it was filled with current concrete or asphalt on the lowest layer along the journey.

- Well classified and esthetics-friendly materials are typically employed as stone and pavement.

- Gifts are frequently packed with crushed concrete and placed as holding walls or walls of confidentiality (instead of fencing)

- India now has a significant infrastructure shortfall, and understanding how much does aggregate cost is crucial in this context. Yet India is very quickly building its basis. It has become the second largest cement producer in the world only after China in this process of development and reconstruction.

- However, the manufacturing of recycled aggregate concrete is not even in the top 10. The lack of a proper source of concrete in India is one of the major reasons behind this. But the request might be satisfied with the support of nations such as the United Arab States, Saudi Arabia and so forth, the Gulf Cooperation Council ( GCC ).

- Now that the government is preparing its doors for developing new towns, buildings, roads, etc., the doors are open to more RAC production.

Precautions While Using Recycled Concrete Aggregates

- Due to probable lead content, there are problems surrounding the use of painted concrete, including recycled concrete gravel.

- The CERL- The military Engineering Corps having investigated the hazards, the associate in nursing all over that concrete in plant-based paint should be employed safe as a filling, but not a fat-proof cowl as long as it is rooted in soil.

- Some investigations have shown that recycled concrete is robust and robust in less quantities than the native combination. A combination of elements such as the ash can remedy this.

Recycled Concrete Aggregate Price

In US, the price of aggregate per ton and price of crushed concrete depends on the quality and quantity of recycled aggregate at around 15 to 55 dollars per tone, at approximately 18 to 80 dollars per cubic garden and at between 2 to 5 dollars per cubic foot.

Recycled Concrete Aggregate

Recycled aggregate concrete (RAC) is an alternative to using natural aggregate (NA) in concrete. Recycled concrete aggregate (RCA) are aggregates obtained by recycling clean concrete waste where content of other building waste must be very low – below few per cent.

Recycled Concrete

Landscaping: recycled concrete can be used for residential and commercial landscaping projects, including in the construction of retaining walls, raised flower and garden beds, to build yard drainage systems and sized down as decorative gravel.

Recycled Concrete Driveway

Crushed concrete driveways are a much more cost-effective driveway solution compared to gravel driveways, regular concrete driveways, or asphalt driveways. With benefits like the price, sustainability, and the fact that it can never crack and require a repair, crushed concrete is a great driveway option.

Recycled Aggregate

Recycled aggregates is a term that describe crushed cement concrete or asphalt pavement from construction debris that is reused in other building projects.

Recycled Crushed Concrete

Recycled concrete aggregate (RCA) also called “crushed concrete” is made up of asphalt debris from other construction projects that can be reused to create driveways, pathways, garden beds and more. At the same time, new concrete is being created to begin the process all over again.

Crushed Concrete for Landscaping

Crushed concrete can be used to outline a small patio or it can be used on large-scale commercial properties for landscaping additions. It is environmentally friendly landscaping material. It is entirely eco-friendly because it is made of recycled materials.

Recycled Concrete Aggregate Cost

Recycled Concrete Aggregate Cost\nRecycled concrete aggregate disadvantages include the cost, which in the USA is around $15 to $ 55 per ton, around $18 to $80 per cubic yard, and $2 to $5 per cubic foot, with price, depends on the quality and quantity of recycled aggregate.

Stabilized Crushed Concrete

Southern crushed concrete’s cement-treated base (CTB) is a mixture of crushed concrete combined with carefully measured amounts of cement that harden after compaction to form a durable paving material.

Recycled Cement

Recycled cement can be produced from cement paste waste. A sustainable way to manage the construction waste was put forward. Recycled cement can have similar properties as ordinary Portland cement. Recycled cement had a lower emission of co2 and lesser energy consumption.

Crushed Concrete

Crushed concrete can be used in a variety of circumstances. It’s used by homeowners, contractors, and landscapers as a practical material for general problem-solving like creating a base for a driveway, garden beds, or overall construction purposes.

Price of Recycled Concrete.

The price of recycled concrete is 0–10% higher than that of virgin concrete. Although there is willingness to purchase green products, clients and consultants emphasize the criticality of material costs before any consideration of environmental impacts.

Crushed Concrete Price Per Yard

Crushed Concrete Prices. Crushed concrete costs $11 to $53 per ton, around $16 to $75 per cubic yard, and $1 to $3 per cubic foot, with prices depending on the quantity.

Crushed Concrete Cost Per Ton

Crushed Concrete Prices. Crushed concrete costs $11 to $53 per ton, around $16 to $75 per cubic yard, and $1 to $3 per cubic foot, with prices depending on the quantity. Leftover concrete and broken asphalt get crushed and recycled, which is a cheaper and more eco-friendly solution for gravel driveways.

Crushed Concrete Driveway Pros and Cons

Here, the prod and cons crushed concrete driveway are as follows.

Pors of Crushed Concrete Driveway

- Good Price

- Good for the Environment

- Easy to Repair

- Abundance of Material

Cons of Crushed Concrete Driveway

- Not So Eye-Appealing

- Potholes Issues on the Driveway

- Not Water-Permeable

Like this post? Share it with your friends!

Suggested Read –

- Pert Critical Path Method

- Largest Roofing Contractors in the Us

- What Is a Cavity Wall | How to Build a Cavity Wall | Cavity Wall Detail | Cavity Wall Thickness | Cavity Wall Insulation Pros and Cons | Brick Cavity Wall

- What Is Oblique Drawing | Oblique Drawing Examples | What Is Oblique View | Oblique Projection | Oblique Shape | Cabinet Oblique | What Is Cavalier Drawing

- Which of the Following Is a Way That Slopes Fail | Types of Slope Failure | Geotechnical Failures | Types of Slopes in Geography | Causes of Slope Failure | Slope Stability

- What Is Pier and Beam Foundation | Advantages & Disadvantage of Pier and Beam Foundations | Pier and Beam Foundation Design | How to Build a Post and Pier Foundation

- What Is Auxiliary Plane | Types of Auxiliary Plane | Types of Auxiliary View | How to Draw Auxiliary View | Drawing Steps for Auxiliary View

- Well Point System | Types of Well Point System | Well Point Dewatering | PVC Well Point | Well Point Installation | Well Point for Shallow Well

- What Is a Cavity Wall | How to Build a Cavity Wall | Cavity Wall Detail | Cavity Wall Thickness | Cavity Wall Insulation Pros and Cons | Brick Cavity Wall

Leave a Reply