What Is Sand Blasting?

Important Point

Commonly called abrasive blasting, grit or sand-blasting can be used to expose the aggregates inside a hardened concrete, giving it a rustic also attractive look, by eroding the surface layer.

There are four typical grades of abrasion, with each one producing a matt finish featuring textures varying from these resembling sand-paper (brush blasting) to more coarse textures (light blasting) and blasting, which exposes large amounts of aggregate (medium, heavy blasting).

Throughout the process, the colour of the cement will initially dominate, and then the sand colour will progressively show with the coarse aggregates being revealed during thick and medium sand-blasting.

or

Sand-blasting is one of the most efficient procedures of cleaning stone, wood, metal, and other solid surfaces. It employs the usage of compressed air to project sand and other granules in a target.

This removes dirt, grime, and all finishes nearly instantaneously. A sandblaster has the ability to restore a surface to the original bare condition with minimal effort.

Even though convenient, treating concrete using a sandblaster requires detailed preparation and protective measures.

Also, read: IS 516:1959 Most Important Point (Method of Tests For Strength of Concrete)

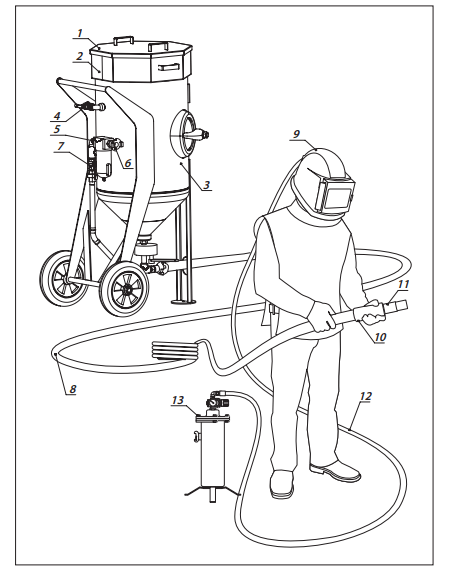

Concrete Sand-blasting Equipment

1. Cover

2. Screen

3. Machine Tank

4. Pressurizing Ball Valve

5. Upper-Air Line Ball Valve

6. Moisture and Oil Separator

7. Lower Air Line Ball Valve

8. Abrasive Blasting Hose

9. Operator Helmet

10. Nozzle Holder

11. Nozzle

12. Breathing Air Hose

13. Breathing Air Filter

Also, read: What Is Inverted Beam | Advantages of Inverted Beam | Purpose of Inverted Beam

Preparation for operation.

• Ensure that the compressor is positioned out of the abrasive blasting operation zone on the downwind side.

• Start the compressor and increase pressure and temperature up to operational values.

• Open lower ball valve at compressed machine air-line (the handle of the open valve should be parallel to the compressed air-line).

• Open the tank venting ball valve.

• Close compressed air feed ball valve (upper ball valve on this compressed air-line).

• Close metering valve FSV by setting adjusting handle in the central position.

• Connect the compressed air hose to the coupling of the machine. Compressed air hose diameter should be at least 0.5″. Lock hose coupling with safety wire or clip.

• Connect abrasive blasting hose to hose the coupling of the machine. Lock hose coupling with safety wire or clip.

• Fill the machine tank with abrasive.

• Put protective equipment on.

Abrasive blasting operations

• Feed compressed air to the machine inlet.

• Machine Maximum Operating Pressure — 10 Bar.

• Close the pressurizing ball valve.

• Upon the signal of this abrasive blasting operator open the ball valve and feed compressed air to the machine line. This tank is pressurized. Only compressed air is expelled from the nozzle.

• Adjust metering valve FSV to provide an optimal air-abrasive mixture. The general rule for abrasive blasting operations: the less abrasive you use, the better.

• To stop operation, close the compressed air feed ball valve and then immediately open the pressurizing ball valve to relieve pressure from your tank.

Also, read: 23 Different Types Cements Available in India and As Per IS Standards

Where Can You Use Regular Sandblast Finish Concrete

• Concrete Steps

• Concrete Walls

• Concrete Pillars

• Concrete Patios

• Concrete Walkways

• Concrete Driveways

• Concrete Pool Decks

Key Benefits

There are key benefits to sand-blasting concrete as an alternative to traditional surface restoration procedures:

• It ensures even concrete finishes in the consistency of their cement and stone ratio in comparison to using conventional procedures.

• Sandblasting is a far more affordable and time-efficient solution than the cost involved with ripping up the concrete, disposing the debris, and then adding a new layer of concrete.

• Its technology uses compressed air to project abrasive material in the concrete for exposed aggregate, hence avoiding irreparable damage to the surface.

• ProStrip Sandblasting can effectively and economically restore concrete to its original surface condition with minimal effort for the preparation of further treatment.

Like this post? Share it with your friends!

Suggested Read

- 10 Best Cement Companies In India

- What Is Rolling Margin | The Procedure of Rolling Margin

- What Is Grouting | Type of Grouting | Advantage of Grouting

- What Is Development length | What Is Development Length of Bars

- What Is Construction Contract | Types of Engineering Contracts | Percentage-Rate Contract

- What Is Unit Weight | What Is Density | What Is Unit Weight Material | Unit Weight Building Materials

- Density of Cement Sand and Aggregate | Cement Density | Sand Density | Aggregate Density | list of Density

It was interesting to learn that sandblasting is a cost-effective way to restore concrete to its original surface without ripping up or replacing it! My concrete driveway has seen a lot of damage over the past few years with oil stains from our cars as well as some large scratches. Getting the driveway sandblasted seems like a simple and easy way to help it look new again. This would be especially helpful since my husband and I are hoping to sell our home in the next six months, and we want the driveway to have good curb appeal.

Thanks