What is Soundness of Cement Test?

Important Point

The soundness of cement test Changes of volume after completion of mold cast. After casting change of volume of molded cement test, this changing call soundness of cement test.

Relevant IS Code: IS 4031 Part 3

Also read: IS CODE FOR CIVIL ENGINEER

Two methods may determine the soundness of cement. as per below

- Le-Chatelier method

- Autoclave method

1. Le-Chatelier Method

Aim of Le-Chatelier Method

To determine the Cement Soundness test use Le-Chatelier method

Apparatus of Le-Chatelier Method

1. Weighing Balance

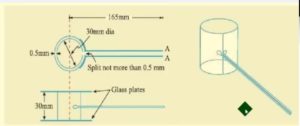

2. Le-Chataleier molds/ Le chatelier apparatus

The test shall conform to IS: 5514-1969*.

3. Miscellaneous ( trowels, tray, stopwatch, etc.)

Procedure of Le-Chatelier Method

- Take 400gm of Cement and find its standard consistency for Cement soundness test

- Place the lightly oiled Le- Chatelier mold on a lightly oiled glass sheet

- Prepare a cement paste formed by gauging cement with 0.78 times the water required to give a paste of standard consistency.

- Fill the Le-Chatelier mold with this cement paste made in step (iii) of the procedure.

- Cover the mold on the top with another piece of a lightly oiled glass sheet.

- Place a small weight on this covering glass sheet and immediately submerge the whole assembly in the water at a temperature of 27° to 32° degree Celsius and keep it there for 24 hours.

- Measure the distance between the indicator points. Submerge the mold again in water. Bring to boiling point in about 25-30 minutes and kept it boiling for 3 hours.

- Removal, the mold from water, allows it to cool and measure the distance between the indicator points. The difference between these two measurements represents the expansion of cement.

Also read : CORE CUTTER METHOD

Water Bath of Le-Chatelier Method

Water bath capable of containing immersed Le-Chatelier molds with specimens and of raising their temperature from 27 ± 2°C to boiling in 27 ± 3 minutes. From IS Code 4031 Part 3 Cl 5.1.4

Calculation of Le-Chatelier Method

Calculate the mean of two values to the nearest 0.5 mm to represent the expansion of cement. From IS Code 4031 Part 3 Cl 5.3

Acceptance Criteria of Le-Chatelier Method

This must not exceed 10mm for ordinary, rigid hardening & low heat Portland cement. If in case the expansion is more than 10mm as tested above, the cement is said to be unsound.

Also Read: LAB TEST ON AGGREGATES AT SITE

2. Autoclave Method

Aim of Autoclave Method

To determine the Cement Soundness test use Autoclave method

Apparatus of Autoclave Method

1. Weighing Balance

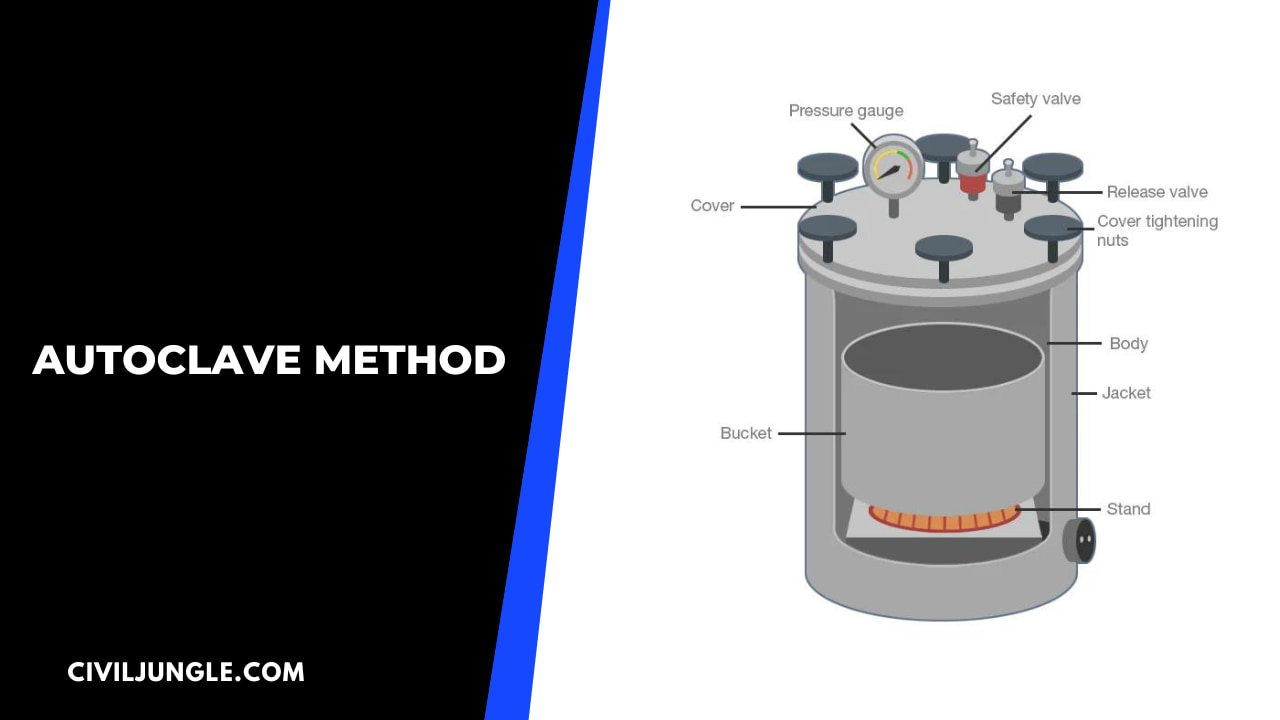

2. Autoclave

3. Graduated Glass Cylinders

Graduated glass cylinders of 150 ml capacity shall be used, The permissible variation on these cylinders shall be plus or minus one milliliter.

The main graduation lines of the cylinders shall be in circles and shall be numbered.

The east graduations shall extend at least one-seventh of the way around, and intermediate graduations shall extend at least one-fifth of the way around the cylinder. The graduation lines may be omitted for the lowest 5 mI. From IS Code 4031 Part 3 Cl 6.1.3

4. Molds

Molds of 25 X 25 mm size and 282 mm internal length and other accessories conforming to IS: 10086-1982

Procedure of Autoclave Method

- At 24 ± t h after molding, the specimens shall be removed from the moist atmosphere, measured for length, and placed in the autoclave at room temperature in a rack so that the four sides of each specimen shall be exposed to saturated steam. For soundness of cement test From IS Code 4031 Part 3 Cl 6.3

- The autoclave shall contain enough water to maintain an atmosphere of saturated steam vapor during the entire period oftest. From IS Code 4031 Part 3 Cl 6.3

- Ordinarily; 7 to 10 percent of the volume of the autoclave shall be occupied by water.

- To permit air to escape from the autoclave during the early portion of the heating period, the vent valve shall be left open until steam begins to vanish.From IS Code 4031 Part 3 Cl 6.3

- The valve shall then be closed, and the temperature of the autoclave shall be raised at such a rate as will bring the gauge pressure of the steam to 2.1 MPa in I to Ii h from the time the heat is turned on.. From IS Code 4031 Part 3 Cl 6.3

- The 2.1 ± O’lMPa pressure shall be maintained for 3 h. At the end of 3 hours period, the heat supply shall be shut off, and the autoclave cooled at a rate such that the pressure will be less than 0.1 MPa at the end of the hour, and any pressure remaining shall be slow-released by partially opening the vent valve until atmospheric pressure is attained.. From IS Code 4031 Part 3 Cl 6.3

- The autoclave shall then be opened, and the test specimens immediately placed in water,

- The temperature of which is above 90°C.

- The water surrounding the bars shall·then be cooled at a uniform rate by adding cold water so that the temperature of the water shall be lowered to 27 ± 2°C in 15 min.

- The water surrounding the specimens shall then be maintained at 27 ± 2°C in 15 min when the samples shall be surface-dried, and their lengths measured again. From IS Code 4031 Part 3 Cl 6.3

Also Read: PROCEDURE FOR RCC CONCRETE

Calculations of Autoclave Method

The difference in lengths of the test specimen before and after autoclaving shall be calculated to the nearest 0’01 percent of the effective gauge length which is the length between the innermost points of the metal inserts used as reference points and shall be reported as the autoclave expansion of the cement. A contraction ( negative expansion) shall be indicated by prefixing a minus sign to the percentage expansion reported. From IS Code 4031 Part 3 Cl 6.3

Soundness Test of Cement Procedure

Apparatus and Materials:

- Le Chatelier’s apparatus (consisting of a small split cylinder mounted on a small glass plate)

- Water bath or steam generator

- Measuring cylinder or graduated vessel

- Stopwatch or timer

- Cement sample

- Distilled water

Sample Preparation:

- Take approximately 100 grams of cement sample and mix it with a known amount of water to form a paste.

- Ensure that the water-cement ratio is as per the desired consistency for the specific test.

Setting Up the Apparatus:

- Fill the water bath or steam generator with distilled water and bring it to a boil.

- Place the Le Chatelier’s apparatus in the water bath, ensuring that the water level covers the split cylinder.

Testing Procedure:

- Place the prepared cement paste into the Le Chatelier’s apparatus. Close the split cylinder with a glass plate, ensuring a proper seal.

- Immerse the apparatus in the boiling water bath or steam for a specified duration, typically 3 hours.

- Start the stopwatch or timer to monitor the time.

Observations:

- During the test, observe if any deformation or expansion occurs in the cement paste.

- Measure the total expansion or contraction of the cement paste by noting the distance moved by the indicator points on the apparatus.

Importance of Cement Soundness Test

The soundness test determines whether hardened cement paste is prone to excessive expansion by boiling the test specimens for a fixed period of time.

Cement Soundness Test Requirements

This must not exceed 10 mm for ordinary, rapid hardening and low heat Portland cements. If in case the expansion is more than 10 mm as tested above, the cement is said to be unsound. Soundness/expansion of cement = L1-L2 L1=Measurement taken after 24 hours of immersion in water at a temp.

Interpretation of Cement Soundness Test Results

The interpretation of cement soundness test results depends on the specific test method used and the applicable standards or specifications. However, in general, the following interpretations can be made:

- Expansion within permissible limits: If the expansion of the cement paste during the soundness test falls within the specified limits set by the relevant standards, it indicates that the cement is sound and does not have any significant potential for delayed expansion or unsoundness. The cement meets the requirements for dimensional stability.

- Excessive expansion: If the expansion of the cement paste exceeds the permissible limits, it suggests the presence of unsoundness in the cement. Excessive expansion may lead to cracking, distortion, or loss of strength in concrete or other cement-based products. It indicates that the cement may not be suitable for use in applications where dimensional stability is crucial.

- No expansion or contraction: In some soundness test methods, such as the autoclave test, no expansion or contraction is considered acceptable. If the cement paste shows no significant change in dimension after the test, it indicates that the cement is sound and does not exhibit any potential for expansion or contraction issues.

Astm Standard for Cement Soundness Test

Soundness test of cement ASTM

The term “soundness” is used to describe cement paste specimens that do not exhibit cracks, disintegration, or other flaws, that result from excessive volume change.

Soundness of Cement Is Code

IS 4031 – Part III

Soundness test of cement is a method used to evaluate the ability of hardened cement to resist expansion caused by certain minerals that are not entirely soluble in water.

Soundness Test of Cement

In the soundness test a specimen of hardened cement paste is boiled for a fixed time so that any tendency to expand is speeded up and can be detected. Soundness means the ability to resist volume expansion.

What Is Soundness of Cement?

The soundness of cement refers to the stability of the volume change in the process of setting and hardening. If the volume change is unstable after setting and hardening, the concrete structures will crack, which can affect the quality of buildings or even cause serious accidents, known as poor dimensional stability.

What Is Soundness?

Soundness, in the context of cement, refers to the ability of the cement to retain its volume after it has hardened. It is a measure of the cement’s stability and resistance to expansion or contraction during setting and curing.

Soundness of Cement Is Tested By

The soundness of cement is mainly tested by two methods: EN-196 (1995), which is based on the Le Châtelier test method, and the autoclave test (ASTM-C151, 2015), in which pressure is also applied to the sample.

Le-Chatelier Method

The Le-Chatelier’s mould is kept on a glass plate and the cement paste is filled in it. The edge of the mould must remain together while filling the mould. The mould is covered by another glass plate and small weight is kept on the top of it to prevent its displacement.

Autoclave Sterilization Temperature and Time

Autoclaves use saturated steam under pressure of approximately 15 pounds per square inch to achieve a chamber temperature of at least 250°F (121°C) for a prescribed time—usually 30–60 minutes. In addition to proper temperature and time, prevention of entrapment of air is critical to achieving sterility.

Autoclave Sterilization Process

The basic principle of steam sterilization, as accomplished in an autoclave, is to expose each item to direct steam contact at the required temperature and pressure for the specified time. Thus, there are four parameters of steam sterilization: steam, pressure, temperature, and time.

Like this post? Share it with your friends!

Suggested Read –

- How to Replace A Fence Post Without Removing Concrete?

- Difference Between Flyover and Bridge | What Is Flyover | What Is Bridge

- What Is Slump Cone Test | Principle of Slump Test | Types of Concrete Slump

- What Is Foundation | What Is Purpose of Providing Foundation | Types of Foundation

- All About Concrete Weigh | How Much Does Concrete Weigh | Why Does Concrete Weigh So Much | How Much Do Concrete’s Ingredients Weigh

Excellent

Thanks, Pankaj

Oh my goodness! An amazing article.

The article is both clear and practical.