What is Brick?

Important Point

One of the oldest building materials in the construction line brick continues to be the most popular and leading construction material because of durable, being cheap, and easy to handle and work with.

Clay bricks are used for building up interior and exterior walls, partitions, piers, footings, and other load-bearing structures. A brick is a rectangular shape and of a size that can conveniently handle with one hand.

Brick may be made of a mixture of sand or burnt clay of sand and lime or Portland cement concrete(PPC). Clay bricks are normally used since they are economical and easily available.

The length, width, and height of brick are interrelated as below:

- Length of brick = 2 x width of brick + thickness of mortar

- Height of brick = width of a brick

The size of a standard brick should be 19 x 9 x 9 cm and 19 x 9 x 4 cm When placed in masonry the 19 x 9 x 9 cm brick with mortar becomes 20 x 10 x 10 cm.

However, the bricks available in most of the country still are 9″ x 4-i x 3″ and are known as field bricks.

The weight of such a brick is around 3.0 kg. (6.61 lbs) An indent called fog, 1-2 cm deep, is shown in as per below, the figure is provided for 9 cm high bricks.

The size of the fog should be 10 x 4 x 1 cm. (100 X 40 X 10 mm ) The purpose of providing frog is to generate a key for holding the mortar and so that, the bricks laid with frogs on top.

Frog is not provided in 4 cm (40mm ) high bricks and extruded bricks.

Also, read: IS Code for Civil Engineer [Q&a]

Properties of Good Bricks

- Good bricks are used for the construction of important structures. They should possess the following qualities

- Bricks should be table-mounted, well-burnt in kilns, copper-colored, free from cracks and with sharp and square edges.

- Bricks should be uniform in standard size and shape.

- Bricks should give clear sound when struck with each other.

- Bricks, when broken, should show a homogeneous and compact structure free from voids.

- Brick should not absorb water more than 15 percent of the weight for first-class bricks and 15 to 20 percent by weight for second class bricks when soaked in water for 24 hrs.

- Bricks should be sufficiently hard. Any impression should be left on the brick surface when scratched with a fingernail.

- Bricks should not be broken into pieces when dropped flat at the hard ground height of one meter.

- Bricks should have low thermal conductivity.

- Bricks, when absorbed in water for 24 hours, should not show deposits of white salts when dried in the shade — dried in the shade.

- The Compressive Strength of brick shall not be less than 55 kg/cm2

Also, read: Core Cutter Method

Sampling of Bricks

It is sampling a lot which shall contain a maximum of 50000 bricks. In case a consignment has to brick more than 50000 brick of the same classification, size, and manufactured under relatively similar conditions, it shall be divided into lots of 50000 bricks or part thereof.

Sampling from the stack shall be divided into a number of real or imaginary sections, and the required number of bricks shall be drawn from each section.

Bricks in the upper layers of the stack shall be removed to enable units to be sampled from places within the stack.

The sample size for Visual / Dimensional Characteristics

|

Sr.No. |

Range | Min. Sample Collection |

| 1 | 2001-10000 | 20-40 |

| 2 | 10001-35000 | 32-60 |

| 3 | 35001-50000 | 50-80 |

Table No 1.

The sample size for Physical Characteristics

- Compressive Strength, Water Absorption Efflorescence. Etc.

| Sr.No. | Range | Min. Sample Collection |

| 1 | 2001-10000 | 5-10 |

| 2 | 10001-35000 | 10-20 |

| 3 | 35001-50000 | 15-30 |

Table No 2.

Also, read: Soundness of Cement Test

Types of Tests On Bricks

- Compressive strength of brick

- Water Absorption test on brick

- Efflorescence test on bricks

- Dimension test on bricks

Also, read: Dynamic Vs Kinematic Viscosity (Difference & Definition)

Test of Brick Compressive Strength (Compressive Strength of Brick)

Relevant is Code

Apparatus

Compression Testing Machine(CTM)

Compression testing machine use of compress of any material as per show riding. So we know how much load in this material.

Scale

The scale used in this test for length, birth & depth of brick.

Wooden Plate

This material used for one between brick both side. Because of the edge of a brick safe in CTM (Compression testing machine)

Also Read: How Many Bags of Concrete in a Yard

Prework Before Compressive Strength of Brick (Brick Compressive Strength)

Remove observed in the bed faces to provide both smooth and parallel faces by grinding.

Immerse in the water at room temperature for 24 hours (1 Day). Remove the drain and the specimen out any surplus moisture at room temperature.

Fill all voids and all fog in the bed face flush with cement mortar (clean coarse sand, the cement of grade 3 mm down ).

Store under the damp jute bag for 24 hours (1 Day), followed by immersion in freshwater for 3 days.

Wipe and Remove any traces of moisture.

Also, read: First Angle Projection & Third Angle Projection Symbol (Orthographic Projection)

Procedure Compressive Strength of Brick (Brick Compressive Strength)

Place the specimen with flat and smooth faces horizontal, and mortar filled face facing upwards between two sides 3 thick ply plywood sheets each of 3 mm thickness and carefully centered between plates of the testing machine.

Apply load uniform rate of 14 N/sq.mm. ( 140 kg f/cm2 ) per minute till failure occurs and notes the maximum load at failure.

Load at failure maximum load in brick at which to produce any further increase in the indicator read reading on the testing machine

- Note:- Plywood sheets plaster of Paris may be used to ensure a uniform surface for the application of load.

Also Read: How Tall Is the Average Doorway

Calculation of Compressive Strength of Brick (Brick Compressive Strength)

As below calculation of test report

- Compressive test of brick N/sq.mm. (Kgf/ sq.cm.)

- = (Maximum load failure in Kgf (N) / Average area of the bed faced in Sq.cm ( Sq.mm)

Conclusion of Compressive Strength of Brick Units

Compressive strength of brick units varied from 4.3 to 6.9 MPa with an average of 5.7 MPa. The average modulus of elasticity was found to be about 3878 MPa., and bricks were found to be soft and weak compared to clay bricks.

Absorption Test on Brick (Brick Water Absorption)

Relevant is Code

- Is Code 3495 part 2

- Aim: To determine water absorption of the specimen by 24 hours immersion in cold water.

- Scope: This procedure covers all relative activity for the project site.

Apparatus (Brick Water Absorption):

- Weighing Balance

- Weight machine for use for brick. Actual weight of the brick and after water absorption of brick weight calculation

Dry Oven

- Dry oven use for Absorption test on brick.

Measuring scale.

- The scale used in this test for length, birth & depth of brick.

Also Read: How Much Does a Yard of Concrete Weigh?

Sample Preparation Absorption Test on Brick (Brick Water Absorption)

- Dimensions shall be a measure to an accuracy of 1 mm of a test specimen

- A dry specimen in an oven at temperature 105-1150C till it attains substantially constant mass.

- the specimen to room cool temperature and obtain weight – M1

Procedure Absorption Test on Brick (Brick Water Absorption)

- Immerse complete dried specimen in clean water at temperature 27+/- 20

- Remove specimen after 24 hours and wipe out any traces of water with a damp cloth.

- Weigh the specimen within 3 minutes after removing from water – M2

Also, read: What is Chain Surveying (Principal, Procedure, Method, Instrument)

Calculations & Records Absorption Test on Brick (Brick water absorption)

% Water Absorption

- = (M2-M1 /M1) x100.

Average of the results obtained shall be recorded.

All results shall be recorded in the respective Format.

Also, read: What Is Bulkage of Sand (Fine Aggregate )

Efflorescence Test On Bricks

Relevant is Code

Apparatus for Efflorescence Test on Brick

- Dry Oven

-

-

-

-

- Dry oven use for Absorption test on brick.

-

-

-

Also Read: How Many Stairs Are in a Flight?

Procedure Efflorescence Test On Bricks

Place the depth of immersion, the end of the bricks in the dish in water being 25 mm.

Place the entire arrangement in a warm (for example, 20 to 30°C) well-ventilated room so that the specimens absorbed all the water in the dish. And the surplus water evaporates.

Cover the whole dish having the brick with suitable glass cylinder so excessive hat evaporation from the whole dish may not occur.

After the water has been absorbed, and the bricks appear to be dry, place the same quantity of water in the dish, and then allow it to evaporate as before.

After the second evaporation, examine the bricks for efflorescence and report the results.

Also Read: Cinder Block Vs Concrete Block

Conclusion Efflorescence Test On Bricks

Nil: When the deposit of efflorescence is imperceptible.

Slight: When the deposit of efflorescence does not cover more than 10 percent of the exposed area of the brick.

Moderate: When the deposit of efflorescence is more than 10 percent but less than 50% of the exposed area of the brick.

Heavy: When the deposit of efflorescence is more than 50 percent, but the deposits do not powder or flake away from the brick surface.

Serious: When the deposits are heavy and powder or flake away from the brick surface. The specifications limit the efflorescence to be not more than moderate (10–50%) up to class 12.5 and not more than slight (< 10 percent) for higher classes

Also, read: Lab Test on Aggregates at Site

Dimension Test On Bricks

Relevant is Code

Apparatus:

- Measuring scale.

- The scale used in this test for length, birth & depth of brick.

Also Read: Best Color Shutters for Red Brick House

Procedure Dimension Test On Bricks

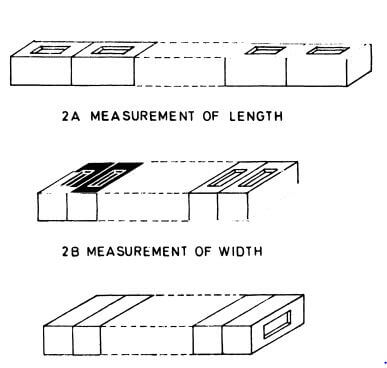

20 pieces out of selected pieces (Table No 1.) are taken and are laid flat as shown in Figure No.1

2 c Measurement of Hight

Dimension Test On Bricks Figure No.1

The tolerances (as per below) on the sizes of bricks are fixed by giving minimum and maximum dimensions, not on individual bricks but on batches of 20 bricks chosen at random.

- For modular size

- length 3720 to 3880 mm (3800 ± 80 mm)

- Width 1760 to 1840 mm (1840 ± 40 mm)

- Height 1760 to I 840 mm (1840 ± 40 mm) ( For 90 mm high bricks)

- 760 to 840 mm ( 800 ± 40mm) ( For 40 mm high bricks)

- For non-modular size

- Length 4520 to 4680 mm ( 4600 ± 80 mm )

- Width 2240 to 2160 tum (2200 ± 40 mm)

- Height 1440 to 1360 mm ( 1400 ± 40 mm )

-

- ( For 70 mm high bricks )

- 640 to 560 mm ( 600 ± 40 mm)

- ( For 30 mm high bricks)

-

Twenty entire bricks shall be selected at random from the sample selected under 8. Loose particles, all blisters of clay and small projections shall be removed.

They shall be arranged upon a level surface successively as indicated in please above figure. 2C, 2B, and 2A in contact with each other and in a straight line. (As per Figure)

The overall (Stright Brick) length of the assembled bricks shall be measured with a tape, other suitable inextensible measure sufficiently (Electronic measurement tape) long to measure the entire row at one stretch.

Measurement by repeated application of short rule or measure shan’t be permitted.

If, it is found impracticable to measure bricks in one row, the sample may be divided into rows of ten (10) bricks each which shall be measured separately to the nearest mm(millimeter).

All these dimensions shall be added together.

Also, read: Procedure for Rcc Concrete

Test on Bricks PPT

Common Burnt Clay Bricks Detail / Strength

| Average Compressive Strength not Less Than |

||

| N/ Sq.mm. | Kgf / Sq.cm. | |

| 35 | 35 | 350 |

| 30 | 30 | 300 |

| 25 | 25 | 250 |

| 20 | 20 | 200 |

| 17.5 | 17.5 | 175 |

| 15 | 15 | 150 |

| 12.5 | 12.5 | 125 |

| 10 | 10 | 100 |

| 7.5 | 7.5 | 75 |

| 5 | 5 | 50 |

| 3.5 | 3.5 | 35 |

| The common burnt clay bricks shall be classified on the basis of average compressive strength as given in the above table | ||

Also, read: What Is Traversing in Surveying | Types | Method | Definition

What Is Brick Strength?

The compressive strength of brick or structural clay tile is an important material property for structural applications. In general, increasing the compressive strength of the unit will increase the masonry assemblage compressive strength and elastic modulus.

Which IS Code for Brick Testing?

As per below IS Code used in brickwork

- IS: 1077 – 1992 (R2002)

- IS: 1200 (Part-III) – 1976

- IS: 2212 – 1991

- IS: 3495 (Part I to IV) 1992 ((R2002)

- IS: 6042 – 1969

- IS: 3590-1966

- IS: 3466 – 1988

Different Types of Brick Test

Types of Tests On Bricks for Construction Purpose

- Absorption test.

- Crushing strength test.

- Hardness test.

- Shape and size.

- Color test.

- Soundness test.

- Structure of brick.

- Presence of soluble salts (Efflorescence Test)

Indian Standard Brick Size

Bricks Sizes as per Indian Standard (IS 1077) Brick sizes based on IS 1077 specification (Common burnt clay building bricks), the standard modular size of common building brick is 190 x 90 x 90 mm or 190 x 90 x 40 mm (length x depth x height).

Value of Water Absorption of Bricks

The acceptable water absorption for clay bricks are between 12% and 20%. If you are using engineering bricks the closer you are to the 12% the better the result will be. When the water absorption is too low, i.e. below 12%, it may be difficult to obtain a proper bond between the mortar and the bricks.

What is the Crushing Strength of a Brick?

Typically, compressive strength or crushing strength of brick is ranging between 1000 psi to 1500 psi, in general, compressive strength of 1st class brick is around 1493 psi, for common building bricks, their compressive strength is around 498 psi, for second class brick, their compressive strength is around 996 psi, for sun dried brick, their compressive strength is around 356 psi, for fly ash brick, their compressive strength is around 1422 psi and for AAC block, their compressive strength is around 570 psi.

What is the Importance of Frog in Bricks?

A frog is a depression in one bearing face of a molded or pressed brick. The frog reduces the weight of the brick and makes it easier to remove from the forms. ASTM specifications C 62 (building brick), C 216 (facing brick), and C 652 (hollow brick) all set limits on the size of frogs

Water Absorption Test on Bricks

Standard Brick Size in India as Per Is Code

The Bureau of Indian Standards has brought out a number of standards on dimensions, quality, strength, classifications, grading and methods of test for metric bricks. ZS 1077 : 1986 and IS 2180 : 1985 suggest two sizes of common building burnt clay bricks, namely 200 mm x 100 mm x 100 mm and 200 mm x 100 mm x 50 mm.

Bricks Compressive Strength

Compressive Strength/ crushing strength of first class brick is 105 kg/cm2. (ii) Compressive Strength/crushing strength of 2nd class brick is 70 kg/cm2. (iii) Compressive Strength/crushing strength of common building brick is 35 kg/cm2

Compressive Strength of Brick

- Compressive Strength/ crushing strength of first class brick is 105 kg/cm2.

- Compressive Strength/crushing strength of 2nd class brick is 70 kg/cm2.

- Compressive Strength/crushing strength of common building brick is 35 kg/cm2.

- Compressive Strength/crushing strength of sun dried brick is 15 to 25 kg/cm2.

Astm Standards for Compressive Strength of Bricks

Grade SW—Brick intended for exposures below freezing in the presence of moisture. Minimum compressive strength requirements are 4,500 psi (31 MPa) for an individual unit and 5,500 psi (37.9 MPa) for an average of three units, based on average gross area.

How to Conduct a Compressive Strength Test on Bricks?

To conduct a compressive strength test on bricks, you will need the following equipment:

- Compressive strength testing machine: This machine applies a compressive load to the brick until it fails.

- Water: For soaking the bricks before the test, if necessary.

- Vernier calipers: To measure the dimensions of the brick accurately.

- Testing accessories: These may include steel plates or plywood sheets to distribute the load evenly on the brick’s surface.

Compressive Strength Testing Machine for Bricks

A compressive strength testing machine for bricks is commonly known as a “brick compression testing machine” or a “brick strength testing machine.” It is used to determine the compressive strength of bricks by applying a compressive load until failure occurs.

Factors Affecting Compressive Strength of Bricks

The compressive strength of masonry depends on several factors such as: mortar strength; unit strength; relative ratio between the mortar and unit strength; relationship between the height of the unit and the smaller horizontal dimension of the unit; orientation of the unit in relation to the direction of the load …

Importance of Measuring Brick Compressive Strength

Compressive strength of bricks is necessary to determine the suitability of load-bearing stones for construction. Bricks are generally used to construct load-bearing masonry walls, columns, and footings. These load-bearing stone constructions mostly experience compression loads.

Comprehensive Strength of Brick

The average compressive strength of brick units is 5.7 MPa, ranging from 4.3 to 6.9 MPa. Was this article useful?

Brick Strength Test

Place the brick between two sheets of plywood with the frog end pointing up. The brick is then placed on the bed of the compressive strength of bricks testing equipment, and axial force is applied at a rate of 140 kg/cm2/minute. (This is quite crucial.) Take note of the force at which the brick collapses (gets broken).

Water Absorption of Bricks Formula

Immerse the dried specimens in clean water at a temperature of 27°C (± 2°C) for 24 hours and wipe out any traces of water with a damp cloth, take the weight (M2). Use the formula Water Absorption of Bricks (%)= [(M2-M1)/M1]x100.

What Is Compressive Strength of Brick?

The standard compressive strength of brick in N/mm2 is given as 10 N/mm² for first class brick and 7.5 N/mm² for second class brick.

How to Calculate Compressive Strength of Brick?

Take note of the force at which the brick collapses (gets broken). The compressive strength of a brick is calculated by dividing this load (P) by its cross-sectional area (A) (Co).

First Class Brick Compressive Strength

The minimum compressive strength for first-class bricks is 10 N/mm². It may be expressed as 105 kg/cm².

Crushing Strength of Brick

The crushing or compressive strength of normal building bricks should not be below 3.5 N/mm².

Standard Compressive Strength of Brick

What is the brick’s compressive strength in megapascals? The average compressive strength of brick units is 5.7 MPa, ranging from 4.3 to 6.9 MPa.

Like this post? Share it with your friends!

Suggested Read –

- Stone Vs Brick

- Plywood Strength

- Water Line Pipe Size

- West Point Bridge Designer

- Introduction of Gantry Girder | Load on Gantry Gutter | Type of Load on Gantry Gutter

- What Is Self Compact Concrete | What Is U Box Text | Equipment U-Box Text | Procedure U-Box Text

- Plaster Calculator | How to Work Plaster Calculator | What Is Plaster Calculation | How to Plaster Calculation for Wall

- What Is Diversion of Headworks (Rivers) | Types of Diversion Headworks | Component Parts of Diversion Headworks (Rivers)

very interesting , good job and thanks for sharing such a good blog