What Is Water Cement Ratio?

It is the ratio of cement and water utilized in the preparation of concrete. The quantity of water used at mixing concrete is very important.

If the percentage of water used is less, then there will not be a sufficient quantity of water to hydrate cement. It will result in weak and porous concrete.

Therefore, the usual tendency is to use too much water that gives a more workable mix, but it doesn’t give sound concrete. Too much water results in the segregation of aggregates and give porous concrete of low strength and low density.

A certain minimum proportion of water is necessary to hydrate the cement completely. To create the concrete sufficiently workable to be placed in position, some more water is needed.

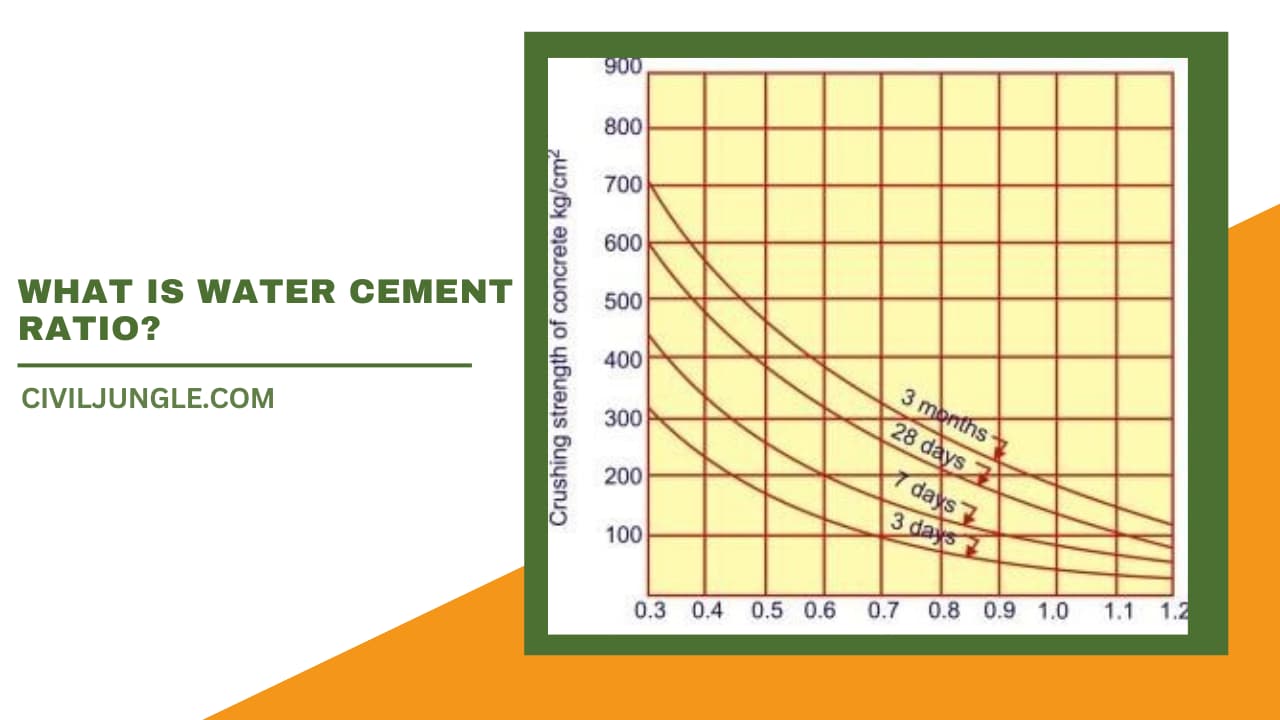

So long as the concrete is sufficiently workable, for the way of placing used, its strength depends on the proportion of water to the cement in the mix.

The water-cement ratio shouldn’t be allowed to exceed the specified limits for various types of concrete and should usually be kept as low as the methods of placing will allow.

Abrahms, as a result of a large number of experiments, states that“with given materials and conditions of the test, the ratio of the quantity of mixing water into the quantity of cement alone determines the potency of concrete as long as the mix is of workable plasticity.“

This is known as water-cement ratio law. According to this law, the strength of concrete won’t increase by simply increasing the quantity of cement unless the water-cement ratio is reduced.

Also, read: What Is Shoring In Construction | Type of Shoring

Required Water-Cement Ratio (British Standard Specifications)

| Proportion | Water-Cement Ratio |

| 1:2:4 | 0.58 |

| 1:1.5:3 | 0.51 |

| 1:1:2 | 0.43 |

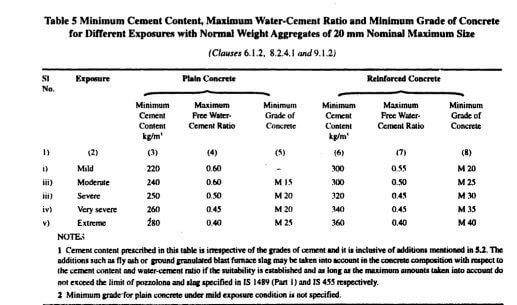

Water-Cement Ratio Table

| Exposure | Plain Cement Ratio | Reinforced Cement Concrete | ||||

| IS 10262 | Minimum Cement Content | W/C Ratio | Grade | Minimum Cement Content | W/C Ratio | Grade |

| Mild | 220 | 0.60 | 300 | 0.55 | M20 | |

| Moderate | 240 | 0.60 | M15 | 300 | 0.50 | M25 |

| Severe | 250 | 0.50 | M20 | 320 | 0.45 | M30 |

| Very Severe | 260 | 0.45 | M20 | 340 | 0.45 | M35 |

| Extreme | 280 | 0.40 | M25 | 360 | 0.40 | M40 |

Different Water Cement Ratios

Different Water-cement ratios are utilized for different concrete applications. For high-quality concrete construction, a lower water-cement ratio of 0.4 could be employed. For concrete construction like sidewalks and drives, a w/c ratio ranging from 0.6 to 0.7 is normally used.

The practical range of water-cement ratio ranges from 0.3 to 0.8, which gives weak and stiff concrete, respectively. Weak concrete means a fairly wet concrete.

Compressive strength of about 5600 psi can be obtained in the concrete of the water-cement ratio 0.4. This value will go down to 2000 psi when a water-cement ratio of 0.8 is used.

Also, read: M30 Concrete Strength

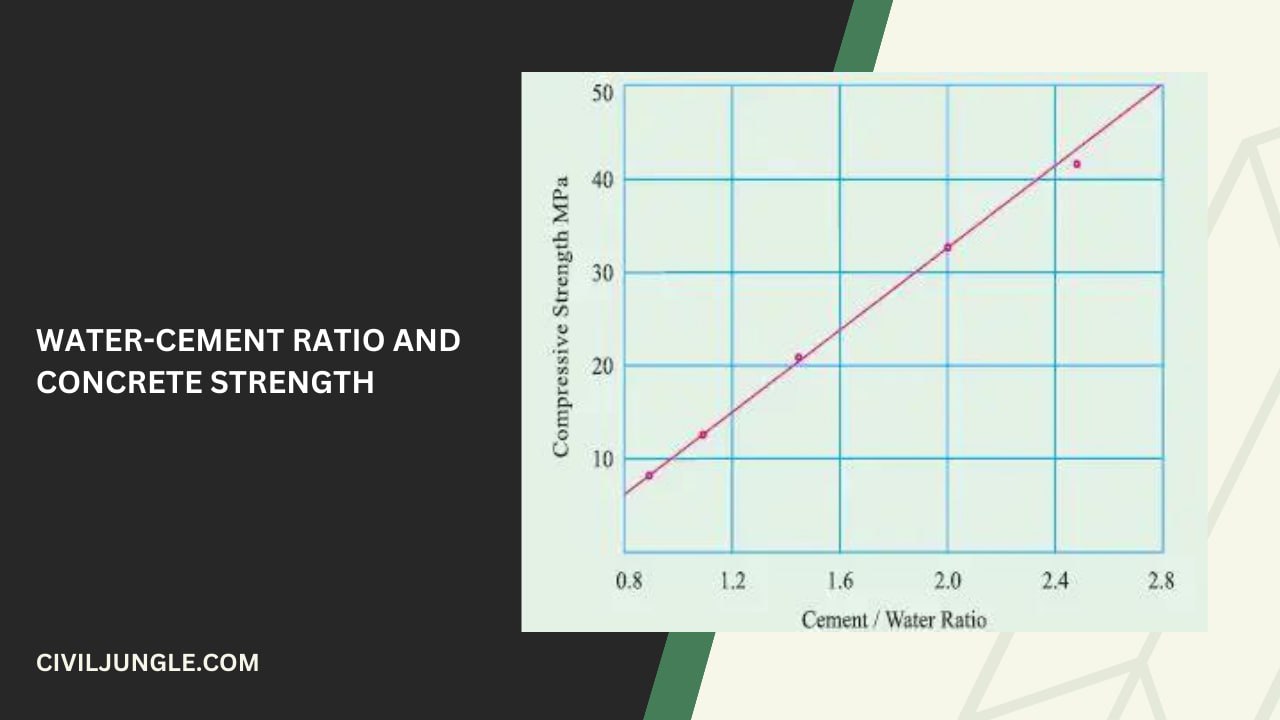

Water-Cement Ratio and Concrete Strength

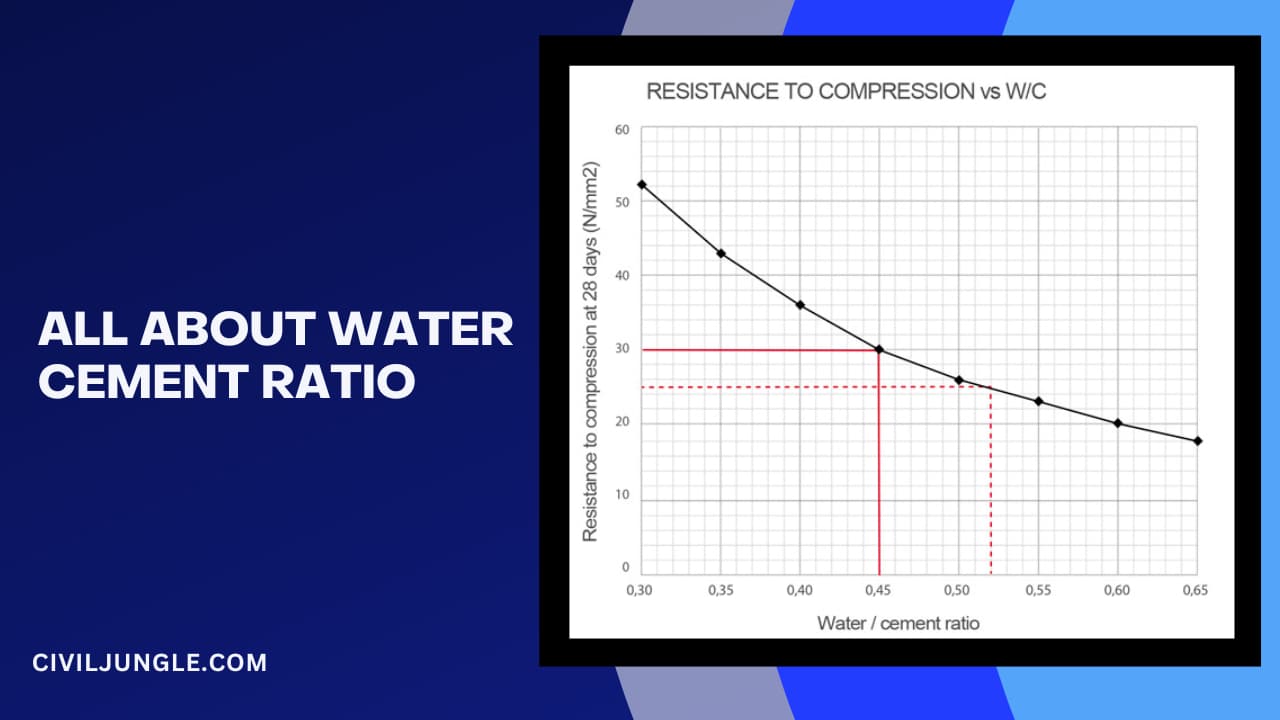

The general concrete strength is reduced with the increase in the water-cement ratio. The addition of more water gives dilute paste, which has more pores at the micro-level.

These make the concrete weak and results in shrinkage and cracks and issues. The Cement and aggregates particles take the excess water that’s present in concrete.

This consumption is uncontrollable if a large excess of water is present in the concrete. Therefore, separate water channels are created, resulting in bleeding on the surface.

This creates weak zones in concrete that are susceptible to cracking under service loads.

A lower water-cement ratio may contribute to high strength and high-quality concrete. But the water-cement ratio alone cannot give good concrete.

A good mix proportion and quality aggregates and binding materials contribute to a good mix design. A low water-cement ratio is thus one of the factors influencing good mix design.

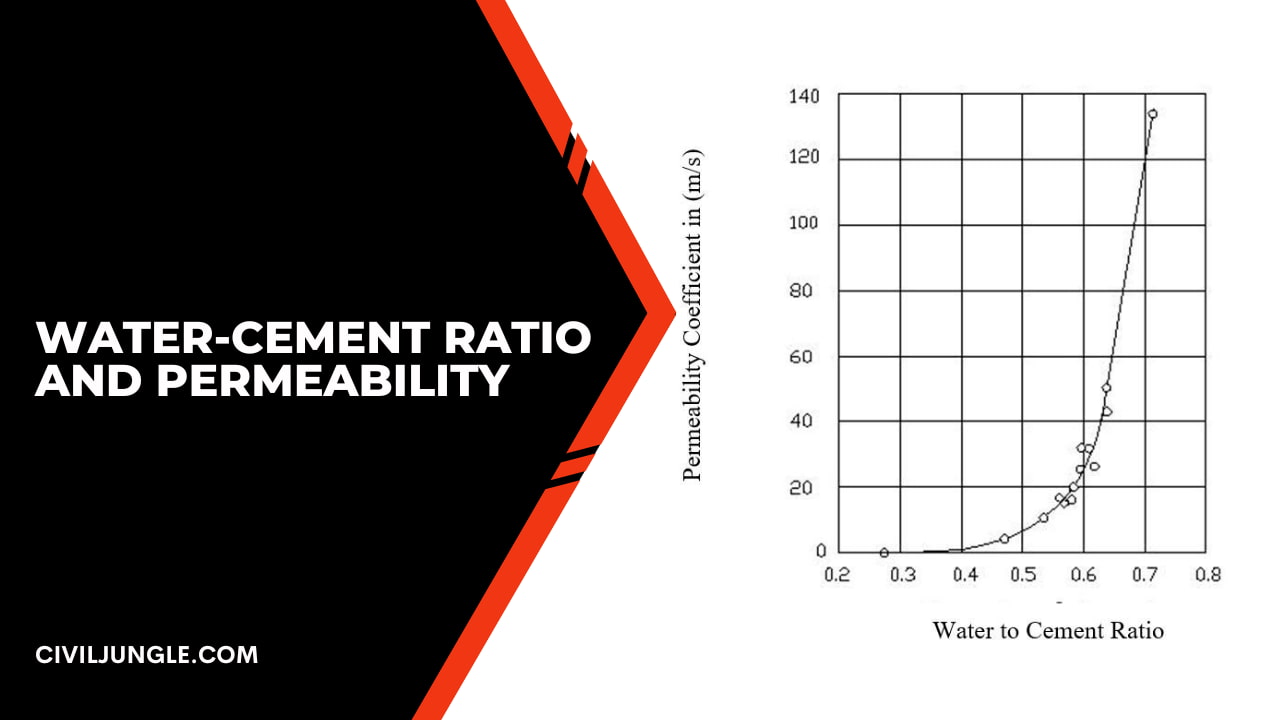

Water-Cement Ratio and Permeability

A mix design using a lower water-cement ratio or higher cement content will give low permeability concrete. A high strength concrete tends to give less pervious concrete.

This will increase the durability of the concrete structure. The above figure shows the relationship between the concrete water-cement ratio and the coefficient of permeability.

Also, read: What Is Well Foundation | Component of Well Foundation

Role of Water in Concrete

It contains micro-ingredients like cement, sand, fine aggregate & Coarse aggregate. To acquire high-strength concrete, that withstands up to our desired compressive strength, We need a correct proportion of admixture to combine those materials.

Here comes the Water, which will initiate this chemical process by incorporating 23% to 25% of the cement volume.

This initiates the chemical process and makes 15% of water-cement paste, also known as a gel, to fill the voids in the concrete.

How to Calculate Water Cement Ratio? – W/C Ratio Calculation

We do not calculate the W/C Ratio. It is selected from various workability tests based on the structural members, transportation, concrete strength, selection of aggregation, etc.

At Site Level, we can make use of the below calculation for the nominal mix.

It is a guide to make your judgment.

Water Cement Ratio as per IS 10262-2009 Table-5

Also, read: What Is Crane | Different Types of Cranes

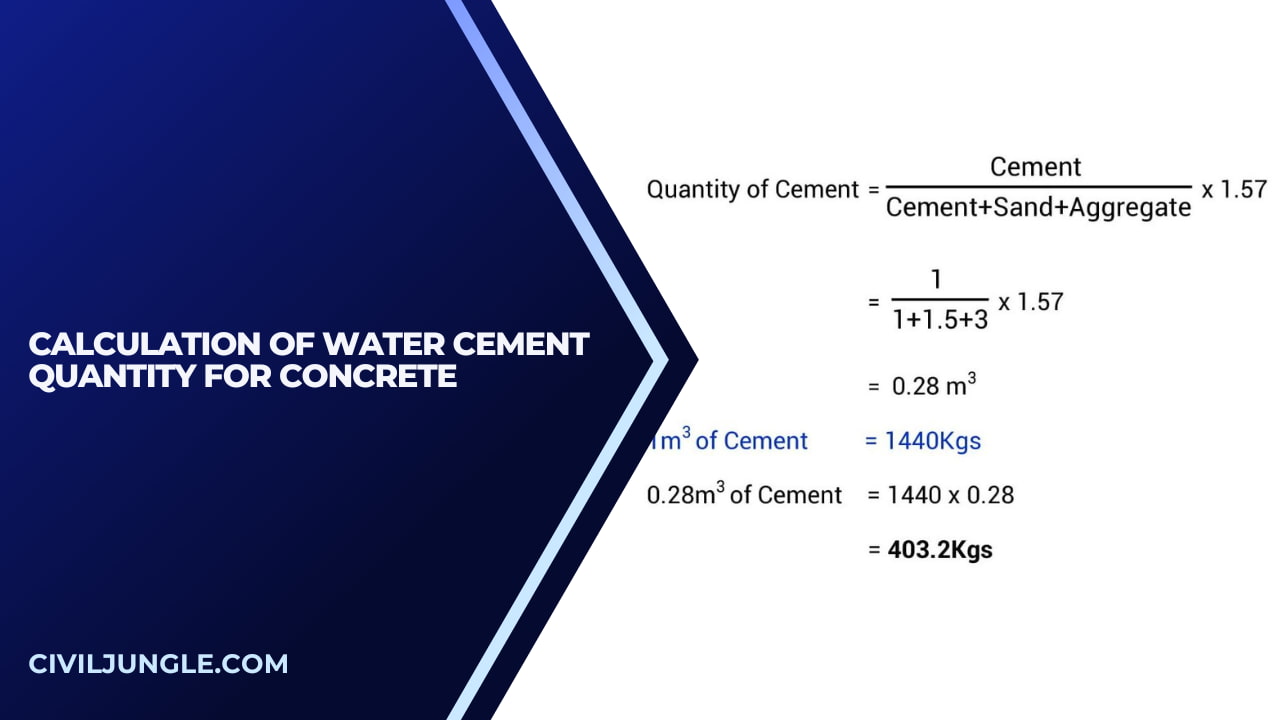

Calculation of Water Cement Quantity for Concrete

- As you can see from the Chart, the W/C ratio varies from 0.4 to 0.7 depending on exposure conditions.

- If we need to calculate Water quantity for concrete, first find the cement content for the volume.

- If we Assume the required cement volume as 50kg,

- The required amount of water = W/C Ratio x Cement Volume

- Therefore, Required amount of water = 0.45 x 50 kg = 22.50 litres / 50 kg cement bag.

- For the Design mix, the W/C ratio will depend upon the workability, strength requirements.

- In IS 10262-2009 Annex-A, they have explained the process for the design mix.

Water Cement Ratio

The water to cement ratio is calculated by dividing the water in one cubic yard of the mix ( in pounds) by the cement in the mix (in pounds). So if one cubic yard of the mix has 235 pounds of water and 470 pounds of cement– the mix is a. 50 water to cement ratio.

Formula to Water Ratio

Concentrated formulas are mixed 1:1 with water. Ready-to-feed formulas do not need any added water. Powdered formulas are mixed 2 ounces (60 mL) of water per each level scoop of powder. Never add extra water because dilute formula can cause a seizure.

Concrete to Water Ratio

A properly designed mixture possesses the desired workability for the fresh concrete and the required durability and strength for the hardened concrete. Typically, a mix is about 10 to 15 percent cement, 60 to 75 percent aggregate, and 15 to 20 percent water.

Water to Weight Ratio

To calculate how much water you should drink daily to maintain a healthy amount of water in your body, divide your weight in pounds by 2 and drink that amount in ounces. For example, a 180-pound person should aim for 90 ounces of water, or about seven to eight 12-ounce glasses, each day.

Ideal Water Cement Ratio for Concrete

The water-cement ratio is the weight of the water in your concrete relative to the weight of cement. Normally, according to IS code 10262 (2009), your nominal mix should have a ratio between 0.4 and 0.6.

Water Cement Ratio for High-Strength Concrete

Water–cement ratios in the range of 0.40 to 0.60 are typically used. For higher-strength concrete, lower w/c ratios are necessary, along with a plasticizer to increase flowability.

Low Water Cement Ratio Benefits

A lower ratio leads to higher strength and durability, but may make the mix more difficult to work with and form. Workability can be resolved with the use of plasticizers or super-plasticizers. A higher ratio gives a too fluid concrete mix resulting in a too porous hardened concrete of poor quality.

Importance of Maintaining Water Cement Ratio

Water-to-cement (w/c) mass ratio is important because it controls the mechanical properties and durability of hardened concrete.

Importance of Water Cement Ratio in Construction

A w/c ratio of 0.4 means that for every 100 lbs of cement used in the concrete, 40 lbs of water is added. These two ingredients, cement and water, are responsible for binding everything together. The w/c ratio largely determines the strength and durability of the concrete when it is cured properly.

Water Cement Ratio Formula

The water–cement ratio (w/c ratio, or water-to-cement ratio, sometimes also called the Water-Cement Factor, f) is the ratio of the mass of water (w) to the mass of cement (c) used in a concrete mix: The typical values of this ratio f = w⁄c are generally comprised in the interval 0.40 and 0.60.

Water Cement Ratio in Concrete

What is water cement ratio ? It is the ratio of the mass of water to the mass of cement added to concrete. The water cement ratio formula directly affects the strength & durability of the concrete. The typical water-cement ratio varies between 0.40 – 0.60 for different grades of concrete mix.

How to Calculate Compressive Strength of Concrete?

Calculating the compressive strength of concrete requires a formula: CS = F ÷ A. The variables in the compressive strength of concrete formula are as follows: CS is compressive strength, F is the force at the point of failure, and A is the cross-sectional surface area. Now let’s define a few terms.

How to Calculate Water to Cement Ratio?

The water to cement ratio is calculated by dividing the water in one cubic yard of the mix ( in pounds) by the cement in the mix (in pounds). So if one cubic yard of the mix has 235 pounds of water and 470 pounds of cement- the mix is a . 50 water to cement ratio.

What Is an Average Water-Cement Ratio for Regular Strength Concrete?

Normal for ordinary concrete (sidewalks and driveways): 0.6 to 0.7. Specified if a higher quality concrete is desired: 0.4.

Water Cement Ratio

More water is therefore used than is chemically and physically necessary to react with cement. Water–cement ratios in the range of 0.40 to 0.60 are typically used. For higher-strength concrete, lower w/c ratios are necessary, along with a plasticizer to increase flowability.

Quikrete Fast Setting Water Ratio

Add 1 part water to 5 – 5 1/2 parts QUIKRETE® Quick-Setting Cement by volume. Reducing the water will hasten the set time.

Quikrete Water Ratio

Final water content should be approximately 6 pt to 9 pt (2.8 L to 4.3 L) of water per 80 lb (36.2 kg) bag of concrete.

Like this post? Share it with your friends!

Suggested Read –

- Consistency of Cement

- Unit Weight of Cement

- Standard Water Line Size

- Workability Concrete

- Difference Between Fine and Coarse

- What Is Concrete | 31 Different Types of Concrete

- What is Salt Concrete Finish | How to Create a Salt Finish

- Difference Between One Way Slab and Two Way Slab | What is Slab

- What Is Sand Blasting | Concrete Sand-blasting Equipment | Key Benefits

- What Is Standard Proctor Test & his Detail | Procedure Standard Proctor Test

- What Is Measurement Book | How to Write Measurement Book | Recording Measurement Book

- What Is Structural Settlement | -Causes For Structural Settlement | What Is Soil Settlement & Foundation Structural Settlement

Sir I need you advice/ guidance for carrying out renovation of my toilet which is situated on the ground floor.The civil contractor has suggested brick bat coba for water proofing after excavating the existing floor tiles .As brick bat coba is time consuming and on reading your articles on micro concrete could I use micro concrete for water proofing of the toilet floor instead of the conventional method of brick bat coba.if I could use micro concrete do provide the correct methodology to be adopted for application along with the time for curring.Looking forward to your valuable inputs.