Introduction of Bridge

Important Point

Human beings have been constructing pier bridges for about four thousand years.

The oldest and still existing bridge in the world is perhaps the Zhaozhou Bridge in Hebei Province in China, originally constructed approximately in A.D. 600.

However, bridge design and construction then may not be considered bridge engineering practice by today’s definition. Instead, work was done based more on experience as opposed to quantitative planning as done now.

Bridge engineering today uses calculus-based analysis and detailed planning.

Materials used in bridge construction have also changed noticeably through a good number of years, from mainly natural materials such as stones and wood than to mainly man-made materials such as steel and Portland cement concrete today.

Due to great improvement in the strength and production quality control of these materials, bridge components have become smaller, thinner, skinnier, and lighter to reduce self-weight and be more economical.

In 1866 Ways and Koenen in Germany conducted a series of tests on reinforced concrete beams (Heins and Lawrie, 1984), which started the era of concrete for bridge construction.

More tests and research work were done in the following decades. The first bridge using reinforced concrete in the world was credited to Monier in 1867 (Heins and Lawrie, 1984).

The first bridges using steel are believed to be constructed in the United Kingdom and the United States in the 1880s.

These pioneering projects began what is known today as modern bridge engineering. Another important aspect characterizing modem bridge engineering is the tools used to perform quantitative modeling and planning.

They include calculus and calculus-based mechanics, acknowledged as the foundation of modem bridge engineering as practiced today.

This knowledge was established in the seventeenth century.

With the new materials and advanced analysis tools, the fast development of modem bridge engineering had its technical strength.

The fuel for substantial developments of bridge engineering was the need or desire for economic development, For example, today’s highway bridge technology in the United States is largely a result of the rapid development of the interstate highway system in the 1950s and 1960s after World War II.

As a product, a comprehensive highway system has been established, consisting of about 50,000 miles of roadways and about 600,000 bridges.

It is also interesting to mention that a number of developing countries are currently experiencing a similar “boom” in their surface transportation systems.

This has become the driving force for bridge engineering development in those parts of the world.

Also, read: Classification of Bricks

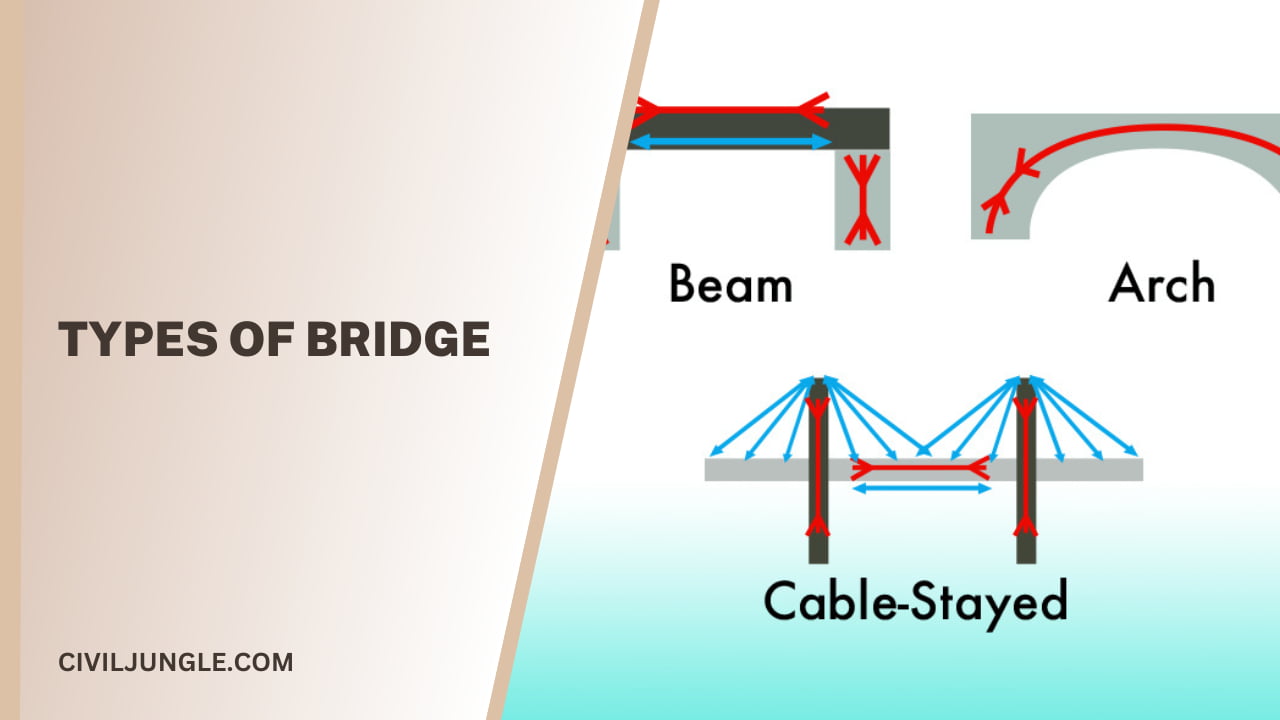

Types of Bridge

- Bridges by Structure

- Arch Bridges

- Beam Bridges

- Truss Bridges

- Cantilever Bridges

- Tied Arch Bridges

- Suspension Bridges

- Cable-Stayed Bridges

- Fixed or Moveable Types

- Fixed Bridges

- Temporary Bridges

- Moveable Bridges

- Pedestrian Bridges

- Types by Use

- Pedestrian Bridges

- Double-decked Bridges

- Train Bridges

- Pipeline Bridges

- Aqueducts

- Commercial Bridges

- Types by Materials

- Natural Materials

- Wood

- Stone

- Concrete and Steel

- Advanced Materials

- Fictional and Mythical Bridges

Also, read: Difference Between Bridge and Culvert | What Is Bridge | What Is Culvert

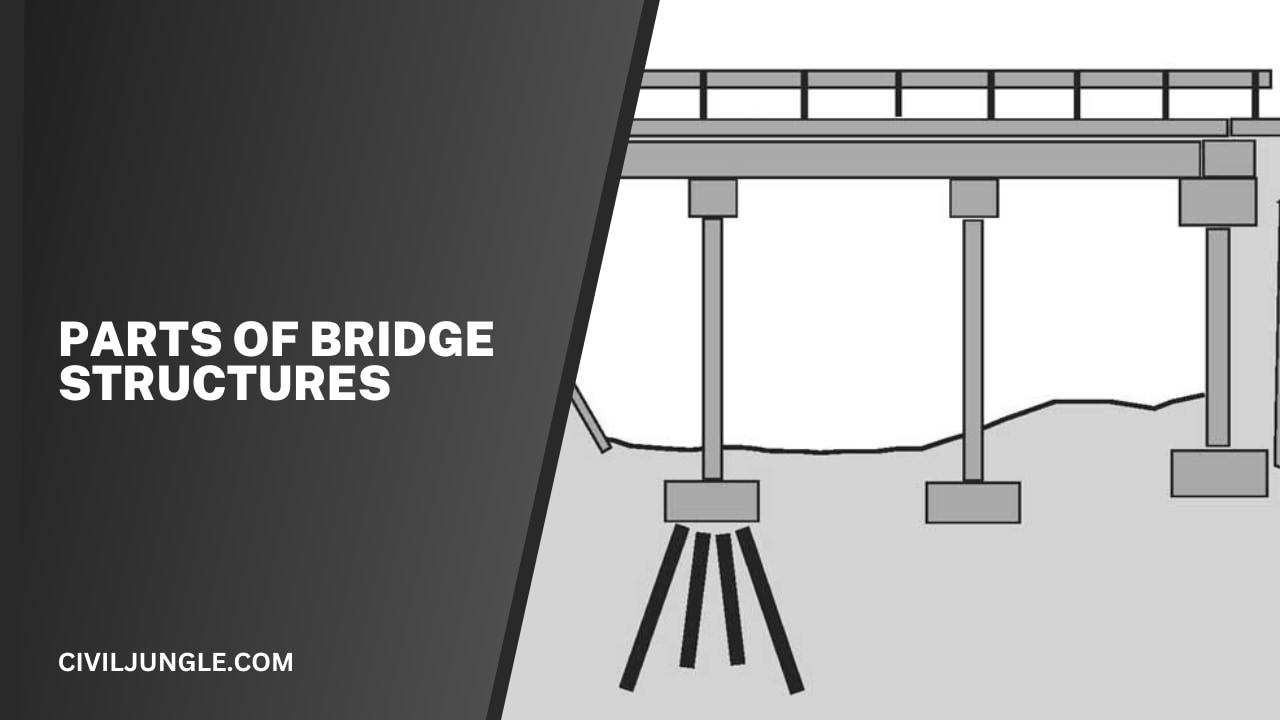

Parts of Bridge Structures

- Major Parts of Bridge Structures as below

- Superstructure

- Decks

- Bearings

- Foundation

- Girder or Beam

- Substructure Components

- Bridge Tower

- Pier Cap

- Pier

- Pile Cap and Piles

- Bridge Anchor

- Suspension Cable

What is Pier?

Although piers are designed to resist vertical loads, it is becoming common to design piers into resisting high lateral loads caused by seismic events.

Even in some low seismic areas, designers are paying more attention to this ductility aspect of the design.

These Piers are predominantly constructed using reinforced concrete.

This Steel, to a lesser degree, is also used for piers.

The Steel tubes filled with concrete columns have gained more attention recently.

The piers or columns for conventional bridges, such as grade separations, overcrossing, overheads, underpasses, and simple river crossings.

Reinforced concrete columns will be discussed in detail, while steel and composite columns will be briefly discussed.

Substructures for arch, suspension, segmental, cable-stayed, and movable bridges are excluded from the substructures for some of these special types of bridges.

Bridge Piers

The bridge piers can be constructed to be substantially attractive and strong in order to withstand both vertical and horizontal loads.

Also, read: What is Plum Concrete | Application | Mix Design | Methodology

Types of Bridge Piers

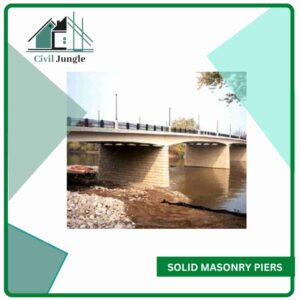

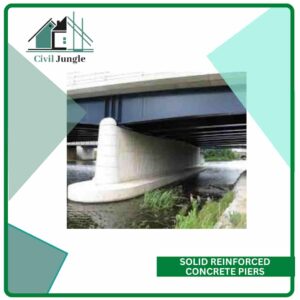

1. Solid Piers

a. Solid Masonry Piers

b. Solid Reinforced Concrete Piers

2. Open Pier

a. Cylindrical Piers

b. Column Piers or Column Bent

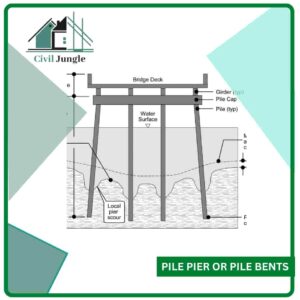

c. Pile Pier or Pile Bents

d. Trestle Pier or Trestle Bent

e. Masonry Piers

f. Mass Concrete Piers

g. Reinforced and Prestressed Concrete Piers

h. Fixed Piers

i. Hammerhead or Cantilevered Piers

j. Special Shaped Bent

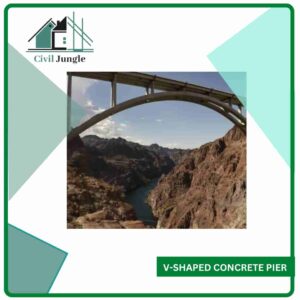

k. V-Shaped Concrete Pier

Function of Piers in Bridge

According to the definition, The Piers, are the vertical support structures of bridges. They are the intermediate supports, whose function is to transmit the forces they receive from the load-bearing elements to the foundations.

What Are Piers in House Construction?

In architecture piers can be defined as an interchangeably for several different building elements. In general, it is an upright support for a structure or superstructure, but it can also refer to the sections of load-bearing structural walls between openings and different types of column.

Types of Piers in Bridges

- Solid Piers. Solid piers possess solid and impermeable structure, and usually constructed from bricks, stone Masonry, mass concrete or reinforced concrete.

- Open Piers.

- Masonry Piers.

- Mass Concrete Piers.

- Reinforced and Prestressed Concrete Piers.

- Fixed Piers.

- Free Piers.

- Hammerhead or Cantilevered Piers.

Types of Pier Cap

There are three types of pier caps: solid capstones, open capstones, closed capstones.

Pier Foundation Types

Types of Pier Foundation

- Masonry piers.

- concrete piers.

- Drilled caissons or piers.

- Timber piers.

- Steel piers.

Pier Construction Methods

Bridge piers are generally concrete columns and are constructed as follows: • fixing a grillage of steel reinforcement for piers to the starter bars; erecting vertical formwork for piers with shores and bracing; • placing and vibrating concrete into formwork for piers; and • stripping shutters and curing concrete.

Do It Yourself Concrete Pier Foundation

How to Build a Concrete-Pier Foundation

- Step 1: Layout the Foundation.

- Step 2: Prepare the site.

- Step 3: Mark the border.

- Step 4: Dig the Pier Holes.

- Step 5: Prepare the Fiber-Form Tubes.

- Step 6: Install the Tubes.

- Step 7: Mix and Pour the Concrete.

- Step 8: Cure the Concrete.

Pier Foundation Is Also Called

It is also known as “Post foundation” of “Column Foundation”. Piers are often used in areas where the ground is not stable enough to support other traditional foundation types.

Difference Between Pile and Pier Foundation

The main differences between the pier and pile foundation are given below. In pile foundation, the loads are transferred by means of vertical timber, concrete or steel. Pier foundation consists of cylindrical columns to support and transfer large superimposed loads to firm strata.

Based on What We Differentiate Between Pile and Drilled Pier

Piles are driven through the overburden soils into the load-bearing strata. Piers are drilled with the drill machine. Pile foundations transfer the load through friction (in case of friction piles) or through both friction and bearing ( in case of combined end bearing and friction piles).

Concrete Pier Foundation Spacing

While 8 to 10 feet apart is a sufficient distance for foundation piers to support most structures that would sit atop a post and pier foundation, if the building is particularly tall or made of heavier materials such as brick or metal, it’s not uncommon to place the foundation piers even closer together.

Pier Spacing Requirements

Depending on the structure’s dimensions and weight, the piers typically are spaced 5 to 10 feet on center apart around the perimeter. The open space inside the structure’s outer walls also needs to be supported if it has to support a floor or structural components, such as posts.

What is the function of piers in bridges?

Piers in bridges are vertical support structures that transmit forces from load-bearing elements to foundations. They serve as intermediate supports, ensuring the stability and structural integrity of the bridge.

How are piers defined in house construction?

In house construction, piers can refer to upright supports for structures or superstructures. They might denote load-bearing structural wall sections between openings or different types of columns, contributing to the building’s stability.

What are the types of piers in bridges?

There are several types of piers in bridges, including Pier bridge definition: Solid Piers, open piers, masonry piers, mass concrete piers, reinforced and prestressed concrete piers, fixed piers, free piers, and hammerhead or cantilevered piers.

What are the types of pier caps?

Pier caps can be categorized into three types: solid capstones, open capstones, and closed capstones.

What are the types of pier foundations?

Types of pier foundations include masonry piers, concrete piers, drilled caissons or piers, timber piers, and steel piers.

How are bridge piers constructed?

Bridge piers are typically concrete columns constructed by placing a steel reinforcement grillage for piers, erecting vertical formwork, pouring concrete into the formwork, and then removing the formwork and curing the concrete.

Like this post? Share it with your friends!

Suggested Read –

- Pier Pile Cap

- What Are Tunnels

- Bridge Abutment Wall

- What Is a Flyover Bridge

- Cantilevered Foundation

- Drilled Pier Foundation

- Procedure for Rcc Concrete

- Cantilever Bridge Definition

- What Is Honeycomb In Concrete | Cause | Cure | Type of Grouting

- What Is Cover in Concrete | Clear Cover in Beams, Slab, Column, Footing

- Concrete Mix Ratio | What Is Concrete Mix Ratio | Type of Concrete Mix Ratio

- Concreting in Construction | Classification | Properties | Grades | Advantage & Disadvantage | Quality Control

Like!! I blog quite often and I genuinely thank you for your information. The article has truly peaked my interest.