What Is Chicken Mesh for Plaster?

Important Point

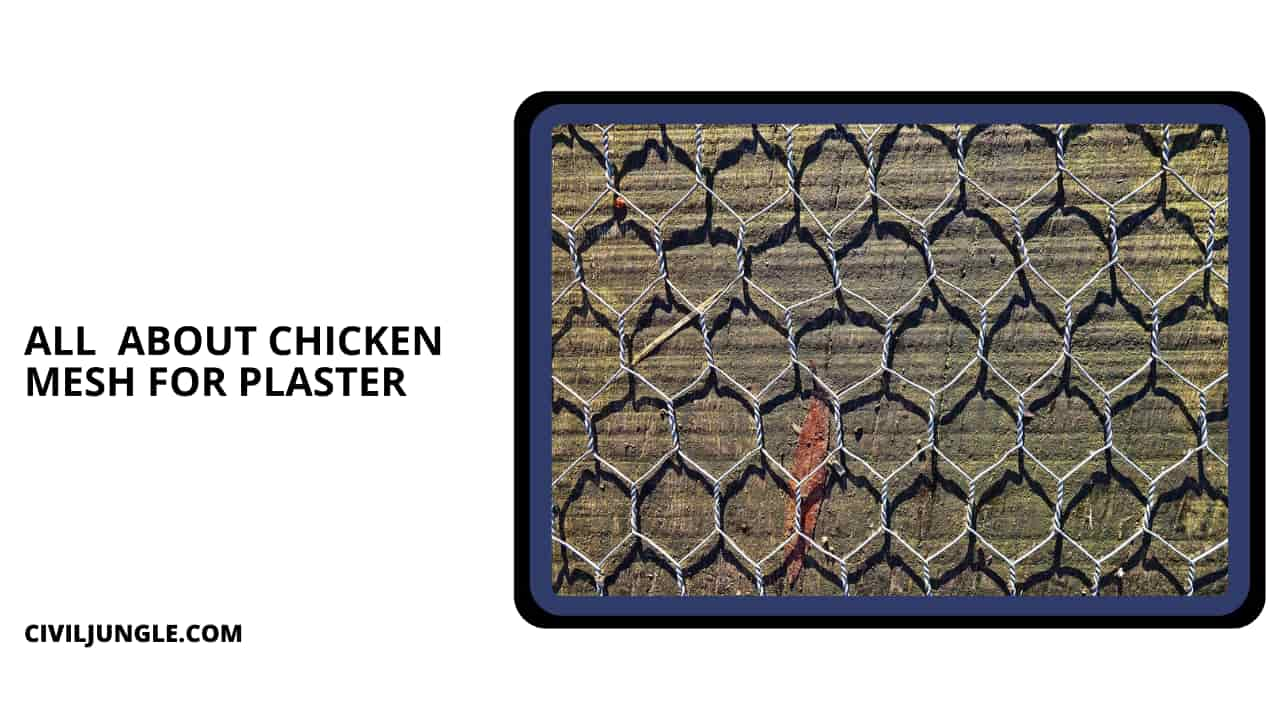

Chicken wire has specific properties for plastering use. Chicken wire mesh is formed by twisting two adjacent wires at least four times, forming a strong honeycomb mesh structure.

So, it has high strength and durability. Using it when plastering effectively prevents plaster layer drying out and cracking.

The hair cracks are mainly formed on the plastering layer. And mainly Hair cracks are often found on the column and brickwork joints. This happens because

Contraction and expansion for concrete occur more when compared to brickworks. Hence there’s a difference between these and thus forms the crack.

Also Read: Plaster Cement Mix

Chicken mesh for plaster material virus three different

Types of Chicken Mesh as Per Material

- Wier Mesh

- Fibreglass Mesh

- Plastic Mesh for Plastering

1. Wier Mesh

As per below, different types of wire mess like.

- Light Type Expanded Metal

- Plaster Chicken Wire

- Welded Wire Mesh

- Chain Link Mesh

1.1. Light Type Expanded Metal

The expanded metal used for plastering

The expanded metal mesh is mostly used as a reinforcing material at the interior decoration, and especially when a plastering work, so sometimes referred to as stucco netting.

This is manufactured from sheet steel blade, which cuts through and uniformly stretched at cells having like the diamond shape.

So, it has no welds or bends, and is durable and very strong, with a low weight. This ribbed surface makes it has the max adhesion.

Each of these materials has its own disadvantages and advantages. But this best currently considered material is the light type expanded metal.

Also, read: What Is Cover in Concrete | Clear Cover in Beams, Slab, Column, Footing

1.2. Plaster Chicken Wire

Small chicken wire mesh

The chicken wire mesh is formed by twisting both adjacent wires at least four times, creating a strong honeycomb mesh structure.

So, it has high durability and strength.

Its hexagonal shape prevents the formation of internal stresses.

Because of its flexible structure, chicken wire mesh is convenient for mounting on angled and curved surfaces. Its other benefits are twisted mesh, no risk of injury at work, and improved corrosion resistance.

As its mechanical properties and special physical, chicken wire is ideally suited for reinforcement plastering in construction, reinforcement waterproofing, leveling floors, and facade work.

Also, read: What Is Workability of Concrete | Factors Affecting Workability | Test |Errors

1.3. Welded Wire Mesh

The welded wire mesh used for inside plastering work

The welded wire mesh is primarily made of thin, low-carbon drawn wire or galvanized wire with a dia. of 1.5mm to 0.4mm, located in mutually perpendicular directions and interconnected by spot welding.

Its wire dia. It is much smaller than this standard welded wire mesh. The welded mesh plastering has a wide scope. It may be used for the building outside and inside the plaster reinforcement.

If used for interior plasterwork and no corrosion material, needs no galvanizing, common carbon wire mesh will work well.

Also, read: What is Plum Concrete | Application | Mix Design | Methodology

1.4. Chain Link Mesh

Chain link fence used as plastering mesh

The chain link Plastering mesh is a type of light chain link fence used to prevent wall cracks because of temperature changes.

This chain-link fence with its lightweight, thin wire from 2.0mm to 0.5mm and small mesh opening from 5mm to 25mm, this is also called mini or micro chain wire fence.

The man is plastering to a wall using a chain-link fence as support mesh Chain link fence used as plastering mesh.

Galvanized wire and low carbon steel and are its main materials. Because of the mesh for reinforcing the plaster surface doesn’t involve direct contact with the grid environment.

This is particularly important in this construction of industrial plants, in which these walls are exposed to high vibration impacts as a result of this machine, presses, and other powerful mechanisms.

Also, read: What Is Honeycomb In Concrete | Cause | Cure | Type of Grouting

2. Fibreglass Mesh

Plaster fibreglass mesh protects the wall surface

The fiberglass mesh is a cheap material that doesn’t burn and is characterized by low weight and high strength.

These properties allow it to be successfully used at this formation of plaster facades, as well as use on ceiling surfaces and internal walls.

This material is widely used for fastening this surface layer in the corners of the room.

This most widely used standard fibreglass plater mesh is the density of 145g/m2 and 165g/m2 for facade work and exterior cladding.

The resistant to alkalis don’t decompose and will not rust over time, it doesn’t emit toxic and harmful substances, has a high resistance to tearing and stretching, protects this surface from cracking and improves its mechanical strength.

Also, read: Concrete Mix Ratio | What Is Concrete Mix Ratio | Type of Concrete Mix Ratio

3. Plastic Mesh for Plastering

Plastic mesh used to plastering to a brick wall

The plaster plastic mesh for fast-drying dry mixes plastering Plastic mesh is recommended for plastering internal and external.

Perform this function of protection against the formation and reinforcing mesh of surface crevices and cracks, increase its mechanical strength, and prevent deformation.

However, its scope isn’t limited to Plastering.

The plastic plaster mesh is also successfully used at painting works and plastering by pouring floors, for sound insulation and heat wall surfaces, for the reinforcement of door and window frames, to protect the facades.

A specially recommended for plaster using fast-drying dry mixes, plastic mesh with large mesh is an alternative to metal plaster mesh.

Also, read: Difference Between Mortar and Concrete | What Is Mortar & Concrete | Type of Mortar & Concrete

Why Use Chicken Mesh For Plaster?

To prevent a crack in plastering work we use chicken mesh at the junction. Different material such between column and wall junction where the coefficient of thermal expansion

Different material is different, and because of that, chances of crack after plastering is bound to occur, that’s why we use chicken mesh.

Chicken mesh has this same function as reinforcement does in concrete. It strengthens the plaster against forces.

Mainly to avoid the crack formed due to insufficient gap filling between RCC column & Brick wall joint.

Therefore we used chicken mesh in plastering, and also due to this, there will a proper bond formation between finishing surfaces of the RCC column & Brick wall.

Chicken mesh in old plaster was used to prevent cracking and hold the plaster together should the house experience settlement.

The mesh also helps fight cracks caused by the twisting of plaster laths. Nowadays, I use galvanized wire mesh screwed to old wooden lath to protect my repairs against cracking.

In exterior plastering, you shouldn’t use chicken mesh if the plastering is thinner than 20 mm since the mesh is not galvanized enough and gives you risk for rust expansion, and then the plastering will fall down before it’s due.

Also Read: Fall Ceiling Meaning

What Is Wire Mesh for Bricks Called?

Brick wall reinforcement mesh is also called brick wall reinforcement welded wire mesh, and there are two types: truss mesh reinforcement and ladder mesh reinforcement. It has continuous lengths of reinforcement that are embedded into the horizontal mortar joint of masonry walls.

What Is Brick Mesh?

Brick wall reinforcement mesh is welded wire sheet for reinforcement concrete construction, and there are two types of this kind of mesh, truss-mesh reinforcement, and ladder-mesh reinforcement. And its feature is that welding spots of warp wire and weft wire are on the same surface. Wire diameter: 2.5–6 mm

What Is Mesh in Plastering?

Plaster mesh helps to form the internal skeleton layers of plaster and putty. In differences of temperature and humidity, under mechanical stress, plaster mesh will provide excellent protection for the plastering layer area. Plaster mesh makes it has a high resistance to wear and able to withstand heavy loads.

Chicken Wire in Concrete

Poultry netting (chicken wire) can be used in concrete, but it is difficult to hold in place, can interfere with larger aggregate flow, and has very little tensile strength.

Best Chicken Mesh for Plaster

Stainless steel mesh is the only type of chicken mesh suitable for plastering applications. It offers countless benefits due to its corrosion-resistant properties. Stainless steel mesh is durable and resilient against rust, which makes it best suited for exterior plastering projects.

Heavy-Duty Chicken Wire Mesh for Plastering

When it comes to plastering, heavy-duty chicken wire mesh is not typically used as a primary material. Chicken wire mesh is commonly used in construction and gardening applications, but it is not specifically designed for plastering purposes.

Chicken Wire Mesh for Exterior Plaster

Here’s a general overview of how chicken wire mesh can be incorporated into an exterior plastering project:

- Surface Preparation

- Chicken Wire Placement

- Attachment

- Plaster Application

- Additional Coats

- Finishing

Galvanized Chicken Mesh for Plastering

Galvanized chicken mesh, also known as chicken wire or poultry netting, is a type of woven wire mesh that is commonly used for various purposes, including plastering applications. When it comes to plastering, chicken mesh can be used as a reinforcement material to provide additional strength and stability to the plastered surface.

High-Quality Chicken Mesh for Plaster Walls

To find high-quality chicken mesh for plaster walls, you can follow these steps:

- Identify Your Requirements

- Visit Local Hardware Stores

- Online Suppliers

- Read Product Reviews

- Consider Brand Reputation

- Seek Professional Advice

Chicken Mesh for Plastering

Chicken mesh, also known as chicken wire, is a versatile material commonly used in construction and DIY projects.

Wall Mesh for Plastering

When it comes to plastering walls, using a mesh can be beneficial in certain situations. Wall mesh, also known as plaster mesh or stucco mesh, is a reinforcing material that helps to provide additional strength and stability to the plaster layer. It is commonly used in areas where the underlying wall surface is uneven or prone to cracking, such as over concrete blocks, masonry, or wood.

Wire Mesh for Plastering

Wire mesh is commonly used in plastering to reinforce the plaster and provide additional strength and stability to the surface. It helps prevent cracks and improves the overall durability of the plastered area. There are different types of wire mesh available for plastering, including galvanized and fiberglass mesh.

Chicken Mesh for Plastering Specification

Material type 👉 Galvanized low carbon wire. Wire gauge 👉 0.5mm to 2mm. Hexagon or honeycomb openings 👉 12mm. to 50mm.

Chicken Mesh Meaning

Chicken wire, or poultry netting, is a mesh of wire commonly used to fence in fowl, such as chickens, in a run or coop. It is made of thin, flexible, galvanized steel wire with hexagonal gaps.

Why Chicken Mesh Is Used in Plastering?

Chicken mesh is an essential component of plastering. It is a reinforcing material that strengthens plaster and prevents cracking and other issues.

How to Use Chicken Mesh in Plastering?

Here’s a step-by-step guide on how to use chicken mesh in plastering:

- Prepare the Surface

- Secure the Chicken Mesh

- Apply the First Coat of Plaster

- Embed the Mesh

- Apply Subsequent Coats

- Finish and Cure

How to Attach Chicken Wire to Brick Wall?

Attaching chicken wire to a brick wall can be done using various methods, depending on your specific needs. Here’s a general step-by-step guide:

- Gather the Necessary Materials

- Prepare the Wall

- Measure and Cut the Chicken Wire

- Position the Chicken Wire

- Mark the Attachment Points

- Drill Pilot Holes

- Attach the Chicken Wire

- Trim Excess Wire

- Double-Check and Secure

Like this post? Share it with your friends!

Suggested Read –

- Finishing Plaster

- Top 10 Tiles Companies in India 2021

- What Is Bridge Pier | Type of Bridge Pier

- Type of Brick in Brick Masonry English Bond & Flemish Bond

- What Is Guniting, Set Guniting Systems , Advantage, Disadvantage

- What Is Specific Gravity Cement | Why We Calculate Specific Gravity Cement | Specific Gravity Test on Cement

- Brick Masonry | 6 Types of Bricks | Types of Brick Masonry Work | 4 Types of Brick Bond | 5 Classification of Bricks Based on Size Modification

One thing I’ve learned at my place of employment is chicken wire and plaster makes a “Faraday Cage” for wireless and cellular signals. We tried to add Wi-Fi to the building, but the chicken wire makes it difficult.

What is best chicken mesh .G I or MS

G.I