History of AAC Block

Important Point

AAC was perfected in the mid-1920s by the Swedish architect and inventor, Dr. Johan Axel Eriksson working with Professor Henrik Kreuger.

It was patented in 1924 & production started in Sweden city Yxhult in 1929. Again “SIPOREX” brand started in 1939.

In 1943 Josef Hebel from Memmingen started his first plant in Germany. In 1978 LCC sSIPOREX” plant started in Saudi Arabia.

In this way, AAC industries slowly started to grow all over the world from 1978 & rapidly cover the market from 2012.

Also, read: How Cement is Made | Cement Ingredients | History of Cement

What Is AAC Blocks?

Another building material we have used in GreenWay Subdivision is autoclaved aerated concrete blocks (AAC blocks) for exterior walls.

AAC blocks can be an excellent Green building material. They provide a solid substrate for exterior stucco or siding and interior plaster or sheetrock.

It is porous, non-toxic, reusable, renewable, and recyclable.

AAC Block full form: Autoclaved Aerated Concrete Blocks

Other names ACC Block

ACC Block full form: Autoclaved Cellular Concrete Block

AAC Blocks Technical Specifications

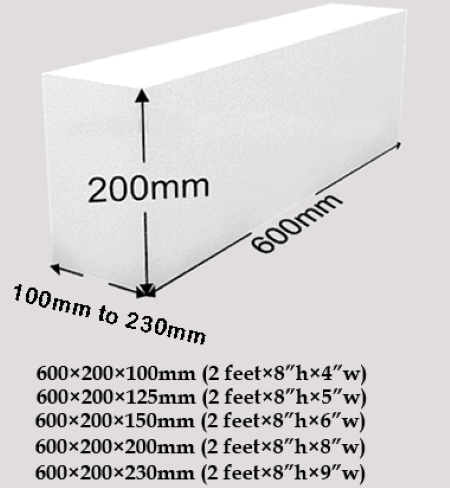

| Sr.No. | Detail | Sizes | Units |

| 1 | Size | 600 X 200 X Thickness | mm |

| 2 | Thickness | 50,75,100,125,150,200,225 | mm |

| 3 | Compressive Strength | > 3 – 4.5 ( IS 2185 ) | N / mm2 |

| 4 | Normal Dry Density | 450 – 650 | Kg / m3 |

| 5 | Thermal Conductivity “K” | 0.16 – 0.18 | W / MK |

| 6 | Thermal Resistance | 0.46 | K-m2 / W |

| 7 | Heat Transmission Coefficient ‘U’ | 2.17 | W / m2k |

| 8 | Drying Shrinkage | 0.04 % ( Size Of Block ) | % |

| 9 | Sound Absorption | Up to 42 | De |

| 10 | Fire Resistance | 2 to 6 | Hrs. |

Uses of AAC Blocks

AAC is well suited for high-rise buildings and those with high-temperature variations.

Due to its lower density, high-rise buildings constructed using AAC require less steel and concrete for structural members.

The mortar needed for the laying of AAC blocks is reduced due to the lower number of joints.

Similarly, the material required for rendering is also lower due to the dimensional accuracy of AAC.

The increased thermal efficiency of AAC makes it suitable for use in areas with extreme temperatures, as it eliminates the need for separate materials for construction and insulation, leading to faster construction and cost savings.

Disadvantages of AAC Blocks

list of AAC blocks Disadvantage

- Cost

- Crack in Walls

- Nailing vs. Drilling

- Installation During Rainy Weather

- Brittle Nature

- Attachments

- Insulation Requirements

| Sr.No. | Detail | Disadvantages of AAC Block |

| 1 | Cost | Cost of production higher than the ordinary concrete block or brick. |

| 2 | Crack in walls | We need to take precautions to eliminate drying shrinkage cracks and stress concentration cracks.

See my answer on the cracking of the AAC block wall. |

| 3 | Nailing vs. Drilling | If you need to fix furniture in the AAC Blocks wall, you need to use a drill bit and a raw plug. You can’t just put a nail. |

| 4 | Installation During Rainy Weather | AAC Blocks are known to crack after installation, which can be avoided by reducing the strength of the mortar and ensuring the blocks are thy during and after installation. |

| 5 | Brittle Nature | They need to be handled more carefully than clay bricks to avoid breakage. |

| 6 | Attachments | The brittle nature of the blocks requires longer, thinner screws when fitting cabinets and wall hangings and wood-suitable drill bits or hammering in.

Special, large-diameter wall plugs are available at a higher mat than common wall plugs. |

| 7 | Insulation Requirements | In newer building codes of northern European countries would require very thick walls when using MC alone.

Thus many builders choose to use traditional building methods, installing an extra layer of insulation around the entire building. |

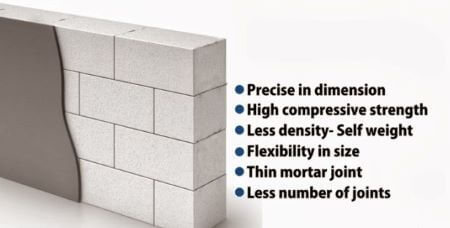

Advantage of AAC Blocks

list of AAC blocks Advantage

• Structural Saving

• Faster Construction

• Acoustic Insulation

• Light Weight

• Eco Friendly

• Water Proof

• High Strength

• Workability and Flexibility

• Fire Resistant

• Pest Resistant / Anti Termite

• Earthquake Resistant

• Non-Toxic

• Great Ventilation

• Precision

• Cost-Effective

| Sr.No. | Detail | Advantage of Block |

| 1 | Structural Saving | AAC blocks reduce the dead weight, which leading to reduce steel consumption in the construction of building due to its lightweight as well as its reduced the consumption of cement and mortar. |

| 2 | Eco Friendly | It produces at least 30% less solid waste than traditional concrete. There is a decrease of 50% of greenhouse gas emissions.

AAC blocks are made by Fly ash or Pond Ash or Sand via a non-polluting process of steam curing comprising of non¬toxic elements. Hence AAC blocks are a more eco-friendly product for construction. |

| 3 | Cost-Effective | • Reduces operating costs by 30P/0 to 40%.

• Reduces overall construction cost by 2.5% as it requires less jointing and reduces the need for cement and steel. • High-insulation blocks save up to 30% in energy costs. o Variety in sizes of blocks helps increase the carpet area • Wall painting and plastering last longer as almost nil efflorescence affects (Brand Name). This translates into lower maintenance costs. |

| 4 | Acoustic Insulation | AAC blocks offer unmatched acoustic insulation. Boost high sound absorption. |

| 5 | Precision | • Available in exact sizes.

• Results in smooth walls with perfect contact between different elements. • Reduces cement and steel usage |

| 6 | Light Weight | AAC blocks are 3 times lighter than traditional bricks, making it easier to transport and reduce the construction time. |

| 7 | Faster Construction | AAC block cut down on construction time by 25 % due to its dimension, lightweight, and leas number of joints. |

| 8 | Earthquake Resistant | The effect of earthquake is proportional to the weight of the structure.

AAC blocks being a lightweight subdues any damage by quakes or high winds largely. |

| 9 | Water Proof | MC blocks have a microscopic cellular structure of aerated pores, which has less water absorption property than regular bricks.

Hence, building built by AAC blocks almost 80 % water-resistant. |

| 10 | High Strength | AAC Blocks have higher strength than regular bricks as compared to regular bricks due to steam curing at high pressure and high temperature. |

| 11 | Workability and Flexibility | MC blocks can be cut easily, drilled easily, nailed easily, and grooved easily.

This allows the installation of electrical and sanitary fitting even after structure construction is complete. |

| 12 | Fire Resistant | Owing to the unique cellular bee-hives like structure, the fire resistance quotient of AAC blocks is very high.

It can withstand up to 1400 ‘C and has a fire rating of 4 to 5 hours. |

| 13 | Non-Toxic | There are no toxic gases or other toxic substances in autoclaved aerated concrete.

It neither attracts rodents or other pests, nor can it be damaged by such. |

| 14 | Great Ventilation | This material is very airy and allows diffusion of water. This reduces the humidity inside the building.

AAC will absorb moisture and release humidity. This helps to prevent condensation and other problems that are related to mildew. |

| 15 | Pest Resistant / Anti Termite | With the precision ratio of AAC Blocks being very high, it results in smooth finishing preventing pests.

The use of inorganic material also inherently prevents algae and fungi growth |

Also, read: What Is Classification of Bricks | Classification of Bricks Different Base

Why AAC Blocks Get Cracks?

Below reason of AAC blocks get cracks

1. Poor Workmanship.

2. Improper curing.

3. Higher thickness of plaster.

4. Use of very fine sand to make mortar i.e., higher silt content or use of sand, which is not graded properly.

5. Shrinkage in blocks or poor quality of blocks may also cause a crack in a wall

6. Continuous vibration or frequent hit by a hammer for nailing may also be a reason for cracks in a wall.

7. The temperature at the time of the application of plaster. i.e., shrinkage cracks are more prone in the summer season than the winter.

Like this post? Share it with your friends!

Suggested Read –

- What Is Dry Pack Mortar | Advantages of Dry Pack Mortar | Disadvantages of Dry Pack Mortar

- What Is Unit Weight | What Is Density | What Is Unit Weight Material | Unit Weight Building Materials

- What Is Hempcrete | Hempcrete Blocks | Advantages & Disadvantages of Hempcrete Blocks | Applications of Hempcrete

- What Is Diversion of Headworks (Rivers) | Types of Diversion Headworks | Component Parts of Diversion Headworks (Rivers)

- What Is Caisson Foundation | Types of Caisson Foundation | Advantage, Disadvantage, Application, & Construction of Caisson

It’s very important also to know that the advantages and disadvantages of aerated concrete usage meets the needs of your construction. Thank you very much for sharing these insights!

thank sir

1) what about capillary action in AAC Block, too many dampness issues observed above skirting level in the wall surface.

2) AAC Block should not be used for External Wall, External Plaster found debonding in later stage, Due to improper Grip.

All size price