What Is Concrete Form?

Important Point

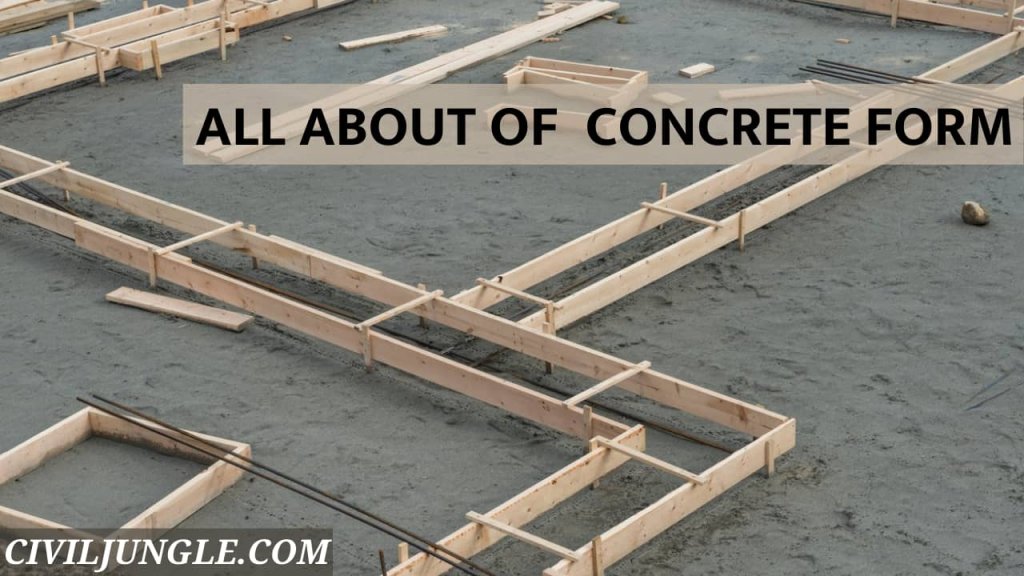

A concrete form is a system of formwork for reinforced cement concrete which is made with rigid thermal insulation.

The concrete formwork is necessary to provide a shape of that concrete.

Types of Concrete Forms, Uses, Advantage, Disadvantages and Thai applications

Also, read: What Is Unit Weight | What Is Density | What Is Unit Weight Material | Unit Weight Building Materials

Types of Concrete Forms

For the concrete casting there are many types of concrete forms are used, that’s are below-

1. Wooden Form

The wooden form is the most conventional and basic type of concrete form, for casting concrete it is mainly used.

The height of the wooden forms should not be exceeding 6 inches.

The wooden form consists of some wooden boards that are tight between either screwed or nailed to get a desired formwork or mold shape.

For the correct level or slope special leveling equipment are used as per requirements.

When we need for laying concrete from any type of free-form design or any curves, then to make the form thin cross-section is employed.

Before pouring the concrete, we ensure that the inside surface of the concrete form should be applied with any form of releasing agent or low-grade oil, so that the concrete does not attach to the boards.

If we properly maintained and cleaned the boards, then it can be used much time for work.

Uses of Wooden Concrete Form

The uses of wooden form are below-

- The uses of wooden form is, when we need for laying concrete from any type of free-form design or any curves, then to make the form thin cross-section is employed.

- The wooden form is the most conventional and basic type of concrete form, for casting concrete it is mainly used.

Advantage of Wooden Concrete Forms

Advantages of wooden concrete forms are below-

- The advantage of wooden concrete forms is, to make any shape of the residential building the wooden concrete forms are used.

- Another advantage of wooden concrete forms is, the wooden form is the most conventional and basic type of concrete form, for casting concrete.

Disadvantage of Wooden Concrete Forms

Disadvantages of wooden concrete forms are below

- The disadvantage of the wooden concrete form is, for the heavy concrete structure, the wooden concrete forms cannot be used.

- A wooden concrete form is most costly.

Application of Wooden Concrete Forms

The applications of wooden form are below-

- The wooden forms can be applied, when we need for laying concrete from any type of free-form design or any curves, then to make the form thin cross-section is employed.

- It may be applying for any residential building construction and industrial construction.

2. Insulated Concrete Form

Insulated concrete form manufactured as a hollow block and used as an insulating material used for constructing building blocks.

On the foundation slab these techniques are constructed and the reinforcement is placed inside these blocks and filled with the required cast or slump concrete.

To get the excessive energy efficiency, the concrete and forms are laid like sandwiches.

By pouring with the concrete in the boards, it is not necessary to remove the board at first as possible.

Uses of Insulated Concrete Forms

- The insulated concrete forms use as insulating materials used for constructing building blocks.

- To get the excessive energy efficiency, the concrete and forms are used like sandwiches.

- The insulated concrete forms can be used as a building designer material.

Advantage of Insulated Concrete Forms

- It can be used for construct building blocks.

- By this we can obtain desired design on the residential building.

Disadvantage of Insulated Concrete Forms

The disadvantage of insulated concrete forms is below

- The disadvantage of insulated concrete forms is, because of it is a hollow block, for this the strength of this concrete blocks is less from the other concrete forms.

- For installation of this types of forms expert workers are needed.

Applications of Insulated Concrete Forms

- The insulated concrete forms can be applied, to make a building block.

- And it also can be applying, for the design of building walls and floors.

3. Foam Concrete Form

The foam concrete form follows non-traditional methods so the specified finish is obtained that the concrete is poured upside down.

This types of forms are manufactured from acrylic glass, melamine, or laminated boards.

By that foam concrete forms, we obtained a creative look, create adverse spaces to the ultimate concrete cast.

Uses of Foam Concrete Form

- The foam concrete form can be used for; the specified finish is obtained and the concrete is poured upside down.

- Another uses of this is, by that foam concrete forms, we obtained creative look, create adverse spaces to the ultimate concrete cast.

Advantage of Foam Concrete Form

The advantages are below of foam concrete form-

- The advantage of foam concrete form is, by this we can obtain a creative look, create adverse spaces to the ultimate concrete cast.

- By this we can decorate the building as our requirement.

Disadvantage of Foam Concrete Form

Some disadvantage of foam concrete form is given below-

- The uses of foam concrete form are costlier in the construction and needed more time for the construction. This is a common disadvantage of this.

- For this expert’s workers are needed.

Applications of Foam Concrete Form

The applications of foam concrete form are given below-

- The applications of foam concrete form are, we obtained creative look, create adverse spaces to the ultimate concrete cast.

- We can be applying for; the specified finish is obtained and the concrete is poured upside down.

4. Concrete Wall Forms

The concrete wall forms techniques we used to make of large space walls, piers, and foundations.

The concrete wall forms are some pre-fabricated formation techniques.

The concrete wall forms techniques are generally made with steel framing from either engineering wooden or solely steel and individual elements are joined together by latches or pins.

In this technique to carry the reinforcement ties are used. When the wall forms are available in numerous shapes and sizes.

For the custom shape, there are have additional producers that’s should be followed as a requirement.

Uses of Concrete Wall Forms

The uses of concrete wall forms are given below-

- The concrete wall forms techniques we used to make of large space walls, piers, and foundations.

- When the wall forms are available in numerous shapes and sizes, in this technique to carry the reinforcement ties is used.

Advantages of Concrete Wall Forms

There have been many advantages of concrete wall forms that are below-

- The common advantage of concrete wall forms is, it can be used to make of large space walls, piers, and foundations.

- Another advantage of concrete wall form is; it can be easily usable.

Disadvantages of Concrete Wall Forms

There have been many disadvantages of concrete wall forms that are below-

- The disadvantage of concrete wall forms is, it is not used for small works like small residential building, etc.

- Another disadvantage of concrete wall forms are its increase the construction cost of the structure.

Applications of Concrete Wall Forms Is

There have been many applications of concrete wall forms that are below-

- We can apply the concrete wall forms, to make large space walls, piers, and foundations.

- For decorating desired shape and size of the structure of a building, we can be applying the concrete wall forms.

5. Steel Concrete Forms

The steel concrete forms are generally manufactured by steel, even 2000 work cycles the stability of steel forms may be achieved, if properly the form used and maintained.

From the wooden concrete forms, it is most durable and more costly.

For decreasing the errors in the concrete forms, steel-concrete forms are used, because of the steel forms do not absorb moisture from the concrete.

Uses of Steel-Concrete Forms

- This form opts-in large-area walls, foundations, piers, etc.

- This is generally made with engineering wood with steel framing.

Advantages of Steel-Concrete Forms

- The main advantage of steel concrete form is its robust, sturdy, and longer lifespan.

- Assembled and removing process is very fast compared to others.

Disadvantages of Steel-Concrete Forms

- It is not economical because the cost is higher.

- The weight of these are too much so it requires lifting equipment.

- Corrosion will easily occur in this.

- Shape and size are limited in this.

Application of Steel-Concrete Forms

- This is generally made with engineering wood with steel framing.

- This form opts in large-area walls, foundations, piers, etc.

Also, read: What Is Concrete | 31 Different Types of Concrete

Free Form Concrete

Here are some details about free form concrete:

- Off-form concrete is a construction material that’s created by pumping concrete through a nozzle to form it into a predetermined shape

- Sprayed concrete is an ideal material for constructing freeform structures because it can form curved shapes

- Wood has been the concrete contractor’s formwork of choice for years because it’s relatively inexpensive, lightweight, and easy to understand and replace

- Plastic concrete forms can be used to create slants or curves, and can work around landscaping obstructions

Concrete forms are solid barriers that help to hold the fluid concrete in place until it hardens and acquires a particular shape.

Concrete Forms

Wooden boards have always been the go-to choice for concrete forms. However, not just any boards will do. A contractor must carefully consider the dimensions of the wood they use, otherwise, the results may not meet expectations.

Round Concrete Column Forms

So you don’t want the screw sideways. Certainly, you don’t want it up what I like to do is just turn it down because then the screw head allows.

Cast in Place Concrete Countertop Edge Forms

The side panels into place to create a slightly rounded edge on your finished countertop slab caulk the edges of the mold with silicone sealant then smooth out with your finger.

Eps Concrete Forms

The word styrofoam™ is often used to describe expanded polystyrene (EPS) foam; however, ‘styrofoam’ is actually a trademarked term for closed-cell extruded polystyrene foam made for thermal insulation and craft applications. Eps foam is the correct term for any form of expanded polystyrene.

Concrete Forming Companies

A concrete finisher is a skilled tradesperson who works with concrete by placing, finishing, protecting and repairing concrete in engineering and construction projects. Concrete finishers are often responsible for setting the concrete forms, ensuring they have the correct depth and pitch.

Fast Form Concrete

The fast-form system offers a lightweight steel forming solution that replaces lumber forms and helps save lumber, time, and money. Fast-form offers a solution for a variety of forming needs.

ICF Block House

Is icf construction less expensive? Insulated concrete forms cost about $150 per square foot, which is 2% to 7% more than standard wood-frame construction. Overall, you’ll likely end up spending about 5% to 10% more in total construction costs than you would for a conventional wood-frame home.

Fast Tube Concrete Form

Fast-tube™ is a utility fabric column form for forming round concrete columns. Manufactured from high-strength polyethylene, fast-tube™ comes on rolls 100′ in length for diameters from 8″ to 12″ (in 2″ multiples) and 50′ lengths for diameters 14″ to 20″. Installation, pouring, and stripping are quick and easy.

ICF Foundation Waterproofing

Waterproofing is a multi-step project, involving many areas of the icf wall and other building components. Moisture control begins with flashing at the roofline, parging at grade level, membranes below grade, air gap barriers, and foundation and site drainage to route water away from the structure.

Patch Holes in Concrete Wall

You simply press that straight into the hole. Make sure that you press that in fairly firmly you want to fill up that hole as much as possible.

Like this post? Share it with your friends!

Suggested Read –

- Finishing Concrete

- Manufactured Sand Concrete

- Difference Between Lumber and Wood

- Introduction of Gantry Girder | Load on Gantry Gutter | Type of Load on Gantry Gutter

- What Is Pier Foundation | Types of Drilled Piers | Advantages and Disadvantages of Drilled Pier Foundations

- What Is Diversion of Headworks (Rivers) | Types of Diversion Headworks | Component Parts of Diversion Headworks (Rivers)

- Parking In India | What Is Parking | Parking Statistics | Types of Car Parking | How to Park a Car Perpendicular | Types of Parking Spaces

- Building Layout | How to Building Layout | What Is Method of Layout of Building | Control Lines of Construction | Construction Layout

- What Is Road Pattern | Different Types of Road Patterns | Grid Pattern Definition | Radial Pattern | Rectangular or Block Pattern | Minimum Travel Pattern

- Definition of Shear Force and Bending Moment | What Is Shear Force | What Is Bending Moment | Relation Between Loading, Shear Force & Bending Moment

Thanks For Information Mr Nikunj