Introduction of Concrete Repair Method

Important Point

Concrete is one of the most widely used building materials in the construction industry all over the world. Concrete is a versatile construction material that possesses various advantages as compared to other construction materials.

There are many defects that occur in the concrete with time due to an aggressive environment. There are many old structures that have reduced their strength in due time. If further use of such buildings continued it will endanger the lives of the people and the surrounding habitat.

Here In this article, we will learn about the various concrete repair methods in detail which are used to repair concrete damage. Concrete repair is basically a modification of the concrete due.

Also, Read: What Is Concrete | 31 Different Types of Concrete

How to Select Suitable Method of Concrete Crack Repair?

The concrete repair method which is adopted for the restoration of this structure mainly depends upon the cause and the extent of the damage.

The concrete repair method is selected based on the evaluation of the crack that occurred in the structure. While treating any damage or crack in the concrete structure it is very necessary that we should know the main cause of that defect.

Knowing the cause of the damage and reducing or eliminating that cause will repair last longer. The selection of the concrete repair method also depends upon the various factors which are as follows. Importance of the structure.

- Availability of Suitable Material.

- The Function of the Structure.

- Nature of the Damage.

- Availability of the Fund.

- What Is Grouting | Types of Grouting | Advantage of Grouting

- What Is Hardened Concrete | Properties of Hardened Concrete

- Why Hairline Cracks in Concrete | Types of Cracks in Concrete

- What Is Spalling Concrete | Causes of Spalling in Concrete | Repairing Concrete Spalding

- What Is Injection Grouting | Types of Injection Grouting | Different Types of Grouting Materials

- Mortar Vs Grout | What Is Motor and Grout | Type of Motor and Grout | Difference Between Mortar and Grout

- What Is Honeycomb In Concrete | Cause of Honeycomb In Concrete| Cure of Honeycomb In Concrete | Types of Grouting

- What Is Shotcrete | Shotcrete & Concrete | Shotcrete Technology | Types of Shotcrete Technology | Advantages of Shotcrete | Disadvantages of Shotcrete

Methods of Concrete Crack Repair

There are various concrete repair methods which are used to repair various types of cracks and damages which generally occur in the concrete.

1. Method of Concrete Crack Repair: Stitching

In the technique of stitching the crack is a bridge up with u shaped metal, you need stitching dogs before being repaired with the rigid resin material.

This can establish restoration of the strength and integrity of the correction due to care is to be given to make an analysis check to ensure that this will perform well under applied loads.

Stitching is the best concrete repair method for Major cracks and it is suitable when tensile strength must be re-established across the major cracks.

Stitching will not close the crack but it is a way of stopping the further movement of active cracks. Stitching will help to prevent cracks from spreading.

Stitching dogs should be of variable length and orientation and so located that the tension transmitted across the crack is not applied to a single plane within the section but is spread over an area.

2. Method of Concrete Crack Repair: Grouting

Grouting is also one of the common and widely used concrete repair methods. Grouting is defined as the process in which the injection of liquid grouting material into the concrete under pressure.

During the process of grouting, the cracks and pores in the concrete get filled with the grouting material which will get subsequently Hardened.

Grouting can be performed the same as the injection of epoxy.

Also Read: Different Washer Types

The Procedure of the Process of Grouting

The step-by-step procedure for grouting are as follows.

- First upon holes are drilled along the crack in this structure and in and around hollow spots.

- If there are several cracks the holes can be drilled in a staggered manner at 500 mm to 750 mm spacing in both directions covering adequately the area proposed to be grouted.

- The holes spacing can be changed as per the requirement and the site conditions.

- The Galvanized Iron pieces ( 12 to 20 mm diameter X 200 mm) with one end threaded or PVC nozzles are fixed in the holes with rich cement mortar.

- All the cracks and annular space around G.I. pipes are filled with rich cement mortar.

- All the cracks are cut open to a ‘V’ shaped groove, cleaned, and sealed with rich cement mortar.

- All the ground holes will be closed with water using the same equipment a day before grouting.

- All holes are first plugged with proper wooden logs are locked in the case of PVC nozzles. The bottom-most plug and the two adjacent plugs are removed and cement water injected in the bottom-most hole under pressure.

- When the cement water comes out through the adjacent holds the injection of cement mortar is stopped and the plugs in the bottommost hole and the one immediately above are restored.

- The process of grouting of concrete cracks is repeated with other holes till all the holes are covered properly.

- It is important that on the day of routing all the flags should be removed in order to drain out the excess amount of cement water and restore before starting the process of grouting.

- The grout should be kept fully stirred under pressure throughout the process of Grouting. The grouting is carried out till refusal and till crowd starts flowing from the hole present at its adjacent.

- A proper record of the quantity of grout injected into each hole should be maintained.

- After the process of grouting, it is very necessary that proper curing should be done for or at least 14 days. All the equipment which are used in the process of grouting should be clean thoroughly after its use.

Precautions Should Be Taken During the Process of Grouting of Cracks in Concrete

- In the case of the arch masonry of the bridges, the grouting is done to strengthen the structure. Some load tests may be carried out in selected structures to satisfy that grouting has helped to reduce the deflection of the crown and spread at the springing to within permissible limit.

- After completing the grouting work, all the equipment which are used in grouting including the slurry and mixing drums, nozzles should be thoroughly washed otherwise cement will get set.

- After the grouting work is completed it should be inspected thoroughly by the expert and should be kept under observation for a period of 6 to 12 months for its behavior after grouting.

3. Method of Concrete Crack Repair: Epoxy Injection

The epoxy injection is the most widely used concrete repair method for cracks which generally develops in beams and columns. The injection of a low viscosity epoxy is a possible repair method for cracks.

This concrete repair method proves to be effective to completely fill the cracks. The epoxy injection is a concrete repair The method is suitable for the treatment of cracks between 0.02 mm and 6mm.

While treating the cracks, care should be taken that the crack must be free of dirt grease, and other types of contamination. This is the best method of crack sealing of concrete.

The use of low modulus and flexible attitude in the treatment of crack will not allow significant movement of the concrete structures.

Before starting this process it is very necessary that the dust should be cleaned by using vacuum cleaning. Compressed air or blasting with water can also be used to remove dust and other contamination from the crack.

If the dust and other contamination are not removed from the crack, then epoxy resin will not form a strong bond in a crack. Epoxy injection is a concrete repair method in which the epoxy concrete is prepared by the addition of epoxy resin with a hardener in the appropriate proportion.

For epoxy injection, high skilled workmanship is required for its application. The injection should start from the bottom and continue until resin appears at the next port.

The injection nozzle is removed from the seal and the nozzle moved up to the next port. It is very just that the pumping pressure should be properly maintained in the cracks.

At the end, when the injected resin gets cured properly the sealing adhesive should be removed by using grinding or cutting.

The various methods of providing entry ports are as follows

- Bonded flush fitting which is attached by the sealing adhesive.

- The drill holes with the systematic fitting inserted and bonded with the adhesives which are used for the purpose of sealing.

- The interrupted seal using a gasket that covers the unsealed portion.

Also, Read: How to Calculate Slab Steel Quantity from Drawing | BBS of Slab

4. Method of Concrete Crack Repair: Grooving and Sealing

Grooving and sealing is the most common and simple Concrete repair method. This technique can be executed with relatively unskilled personnel and can be used to seal both fine pattern cracks and larger isolated cracks.

The system can be used to repair dormant cracks that are of no structural significance and is used to seal the cracks against the increase of moisture and carbon dioxide.

This concrete repair method involves enlarging in the crack along with its export face and sealing it with crack fillers. The care should be taken to ensure that the entire crack is routed and sealed.

5. Method of Concrete Crack Repair: Guniting

Guniting is the concrete repair Method in which the mortar is conveyed through a hose pneumatically to protect at a high velocity onto a surface.

This technique has been developed by introducing a small-size coarse aggregate into the mix. This process is made economical by reducing the cement content. The force of Jet impact on the surface compact the material.

6. Method of Concrete Crack Repair: Shotcreting

The shotcrete process is used for the application of mortar of less thickness. It is also a concrete repair method that is used to repair various damages in concrete structures. Shotcreting works on the same principle of greeting for achieving greater thickness with a small coarse aggregate.

Step by step procedure of shotcreting are as follows.

- Shotcreting is a concrete repair method. The first one removes the Plaster and finishes all around the distressed concrete surface.

- Remove concrete all around the reinforcement in order to get an average 25mm air gap.

- Put the additional information wherever the reinforcement diameter has been reduced by more than 15 to 20%.

- Fix shear key bars of appropriate diameter at a specified spacing in both directions over the surface to be covered with repair materials.

- Apply appropriate passivating and Bond Court over the reinforcement and prepared RCC surface.

- Shotcreting should be done with a 6mm thick finishing coat. It is also necessary to do wet curing over the finished surface of the shotcrete for a minimum period of 7 days.

7. Method of Concrete Crack Repair: Dry Packing Method

Dry packing is a concrete repair method for filling holes and cracks whose depth is at least equal to the smallest surface dimension of the repair area.

The dry pack method is generally used on a small hole in the concrete. The holes should be at least 25 mm deep the dry packing method is not suitable for shallow depressions. The holes go right through the concrete section where the filling cannot be properly rammed.

Dry pack mortar is normally a mix of one part of ordinary Portland cement to 2.5 part of fine sand. The correct measure of the water will produce a mortar that is at the point of becoming rubbery when it is solidly packed.

The holes should be prepared so that they are sharp and Square at the surface edge. The interior surface is to be rubbed and if possible undercut marginally. All repairs and effects to concrete must be removed and the surface of the hole left clean.

Dry should be packed in a layer that has a compacted thickness of about 10 mm. The compacting effort should be directed at a slight angle towards the sides of the hole. The holes should not be overfilled and can be done by pounding on a piece of hardened laid on the surface.

The holes are vertical or overhead surface or not likely to be prepared effectively by this method and epoxy mortar is may be needed. The area to be prepared properly by cleaning and roughened and it should be kept wet for some time.

Repair mortar should be mixed to a plastic consistency and a small quantity of cement mortar should be scrubbed into the surface with the wire brush.

Repair mortar compacted should be a tight Filling around the edges of the hole. It is necessary that proper curing should be done for at least 7 days.

A strong and good bond will get developed between old concrete and repair. The expansive cement or admixtures have been advocated for replacement mortar repair. Generally, the expansive admixtures are used for grouting purposes.

Also, Read: How to Load Calculation on Column, Beam, Wall & Slab

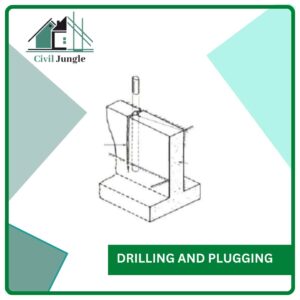

8 . Method of Concrete Crack Repair: Drilling and Plugging

This concrete repair method consists of drilling down the length of the crack and Grouting it to form a key. This concrete repair method is used to repair vertical cracks in the retaining walls.

The hole should be drilled on the crack and the grout key prevents transverse moments of the section of the concrete adjacent to the crack. The key will also help to reduce the heavy leakage through the crack and loss of soil from behind a leaking wall.

Conclusion of Method of Concrete Crack Repair

The above Concrete repair methods are used for repairing concrete defects and cracks which generally occur in concrete structures. The use of the particular concrete repair method varies upon the types.

Also, Read: What Is Composite Masonry | Type of Composite Masonry

How to Select Suitable Method of Concrete Crack Repair?

Appropriate repair materials include epoxies, urethanes, silicones, polyureas, and polymer mortars. For slabs, designers must choose a material with suitable flexibility and hardness or stiffness properties to accommodate both the anticipated floor traffic and future crack movements.

Method of Crack Sealing of Concrete.

Epoxy injection method is used for cracks as narrow as 0.002 inch (0.05 mm). The technique generally consists of establishing entry and venting ports at close intervals along the cracks, sealing the crack on exposed surfaces, and injecting the epoxy under pressure.

Concrete Repair Method

- Removing the deteriorated concrete,

- Forming the sections to be repaired,

- Prepacking the repair area with coarse aggregate, and.

- Pressure grouting the voids between the aggregate particles with a cement or sand-cement mortar.

How to Fix Cracks in Concrete?

- Use a small sledgehammer and chisel to undercut the edges of the crack.

- Clean the area in and around the crack with a wire brush and broom.

- Mix vinyl patching compound as directed by the manufacturer and trowel the compound into the cracks.

- Smooth the mixture with a trowel.

- When the patch has set (see manufacturer’s instructions for the patch compound you’re using), smooth or brush the surface to match the surrounding area.

Also, Read: Properties of Stones | Requirements of Good Building Stones

Repairing Crack in Concrete

Wide cracks in concrete are best patched and sealed with a concrete patching compound. Smaller cracks, less than 1/4 inch wide, can be repaired with a concrete caulk or liquid filler. Patching compounds typically are mixed with water and applied with a trowel.

What Is the Best Concrete Crack Repair Products?

- Bluestar flexible concrete crack filler.

- Ezr hairline crack sealer.

- Red devil pre-mixed concrete patch.

- Pc-concrete two-part epoxy adhesive paste.

- Drylok fast plug hydraulic cement.

- Dalton enterprises 35099 pli-stix.

- Damtite concrete superpatch.

Can You Fill Concrete Cracks with Epoxy?

Epoxy Concrete Repair Crack Treatment and Concrete Crack Filler: A traditional epoxy system to effectively treat static cracks in concrete or minimize their return inactive, structural cracks, and patching concrete.

Will Concrete Sealer Fill Cracks?

To repair the crack, the sealer (or other filler material) needs to penetrate into the crack and fill it completely. Ideally, the sealer has a low surface tension so it readily wets out the concrete and a low viscosity. Keep in mind that materials like epoxy are effective because they wet out the concrete.

Should Concrete Cracks Be Sealed?

Every concrete slab has cracks. Due to the rigid nature of concrete, cracks are inevitable. Uneven drying, shrinkage, and temperature changes can all cause fractures in your slab. Once a crack develops, it’s important to seal it to prevent water seepage and further damage.

Are Hairline Cracks in Concrete Slabs Normal?

Hairline cracks in a concrete slab are rarely a cause for concern. They can be controlled, but not eliminated. A crack in a slab of 1/8 inch or less is typically a normal shrinkage crack and not a cause for concern.

Also, Read:Difference Between Pre-Tensioning and Post-Tensioning | What Is Prestressed | Methods of Prestress

Should I Worry About Hairline Crack?

Hairline cracks in a concrete slab are rarely a cause for concern. They can be controlled, but not eliminated. A crack in a slab of 1/8 inch or less is typically a normal shrinkage crack and not a cause for concern.

How Do You Fix a Crack in a Concrete Patio?

Patch all cracks, crevices, and holes in the old concrete surface. For hairline cracks up to 1/8 inch wide, mix four parts of Ardex Concrete Dressing to one part water. Force the thick paste into the cracks with a putty knife. For larger cracks up to 1/2 inch wide, use concrete–repair caulk.

How to Repair Concrete Crack?

- Use a small sledgehammer and chisel to undercut the edges of the crack. Undercutting the crack makes it wider at the base than at the surface, providing a mechanical method of keying the concrete patch in place for a more secure and permanent repair. For more information, see How to Break Up Concrete.

- Clean the area in and around the crack with a wire brush and broom. Wash the area with a stream of water.

- Mix vinyl patching compound as directed by the manufacturer and trowel the compound into the cracks. Tamp the mixture to remove air pockets with a tamper. If you use patching mortar instead of vinyl concrete crack sealer, either mix it with a bonding agent instead of water or coat the edges of the surface to be repaired with a bonding agent.

- Smooth the mixture with a trowel.

- When the patch has set (see manufacturer’s instructions for the patch compound you’re using), smooth or brush the surface to match the surrounding area.

How to Fill Cracks in Concrete?

Narrow cracks can be filled with a masonry concrete crack filler that comes in a cartridge designed to be used in a caulking gun. Alternatively, you can create a concrete patch with a vinyl concrete patching compound applied and smoothed with a putty knife.

How to Seal Cracks in Concrete?

Quikrete Self-Leveling Polyurethane Sealant may be used. Widen the crack using a chisel and hammer to a minimum of ¼ inch and break away any deteriorating concrete (the edges of the crack should be vertical or beveled in an inverted “v”).

How Do You Repair Cracked Concrete Outside?

Patch all cracks, crevices, and holes in the old concrete surface. For hairline cracks up to 1/8 inch wide, mix four parts of Ardex Concrete Dressing to one part water. Force the thick paste into the cracks with a putty knife. For larger cracks up to 1/2 inch wide, use concrete–repair caulk.

Also, Read: H-Beam vs I-Beam | What Is H-Beam | What Is I-Beam

Types of Cracks in Concrete

- Plastic shrinkage concrete cracks.

- Expansion concrete cracks.

- Heaving concrete cracks.

- Settling concrete cracks.

- Concrete cracks caused by overloading the slab.

- Concrete cracks caused by premature drying.

How to Patch Cracks in Concrete?

Wide cracks in concrete are best patched and sealed with a concrete patching compound. Smaller cracks, less than 1/4 inch wide, can be repaired with a concrete caulk or liquid filler. Patching compounds typically are mixed with water and applied with a trowel.

Can Cracked Concrete Be Repaired?

Wide cracks in concrete are best patched and sealed with a concrete patching compound. Smaller cracks, less than 1/4 inch wide, can be repaired with a concrete caulk or liquid filler. Patching compounds typically are mixed with water and applied with a trowel.

Should You Fix Hairline Cracks in Concrete?

This less evasive crack repair technique breaks the rules for concrete repair. Hairline cracks are not worth the trouble fixing. You have to cut open a hairline crack if you want to actually repair it.

Concrete Wall Repair Methods.

- Scrub it clean.

- Use a nail to align injection points.

- Mix the two-part epoxy crack sealer.

- Spread the sealer onto base.

- Mix and apply a larger batch of epoxy sealer.

- Dispense the LCR epoxy.

- Fill up the ports.

- Cut necks of the ports.

Crack Repair Techniques.

There are several methods of concrete crack repair such as epoxy injection, routing, and sealing, grouting, stitching, drilling and plugging, gravity filling of cracks in concrete. Details of these methods for the selection of suitable methods for different types of cracks in concrete are discussed.

Concrete Slab Repair Methods.

Repair methods and solutions common ways to repair a slab are to surface fill or inject with epoxy or polyurethane. Filling and bonding the slab back together with a high strength epoxy is a great way to seal the crack.

Concrete Crack Repair

Concrete crack repair refers to the process of fixing cracks that develop in concrete structures such as buildings, bridges, sidewalks, or driveways. Cracks in concrete can occur due to various reasons, including shrinkage, settling, heavy loads, temperature changes, or structural issues.

Concrete Slab Crack Repair

Concrete slab crack repair involves fixing cracks that appear in concrete slabs, such as floors, driveways, patios, or garage slabs. Cracks in concrete slabs can occur due to a variety of factors, including shrinkage, settlement, heavy loads, temperature changes, or inadequate reinforcement.

Best Concrete Crack Filler

- Epoxy-Based Crack Fillers

- Polyurethane

- Acrylic-Based Crack Fillers

- Concrete Patching Compounds

Concrete Patio Crack Repair

- Widen the Crack. Widening the crack and creating a V-shape will help the patch materials stick better.

- Clean Out the Crack.

- Add the Solid Crack Filler.

- Apply the Concrete Crack Filler.

- Flatten the Filler.

- Let the Patch Cure.

Grouting Method of Crack Repair

- Crack Assessment

- Preparation

- Grout Material Selection

- Injection Process

- Monitoring and Excess Grout Removal

Best Concrete Crack Repair

Concrete Patching: Patching is a common method for repairing small to medium-sized cracks. It involves cleaning the crack, widening it if necessary, and filling it with a concrete patching compound. Patching compounds can be cement-based or polymer-modified, and they provide a durable and aesthetically pleasing repair solution. They are suitable for cosmetic repairs and non-structural cracks.

Cement Crack Repair

Step 1: Remove the Loose Concrete. Remove any damaged or crumbling concrete.

Step 2: Clean the Concrete. Clean the area in and around the damage with a wire brush and broom.

Step 3: Position the Concrete Patch Form.

Step 4: Mix the Concrete Crack Sealer.

Step 5: Smooth the Concrete Patch.

Concrete Crack Repair Methods

What are the Methods of Concrete Crack Repair?

- Epoxy injection.

- Routing and Sealing of Cracks.

- Concrete Crack Repair by Stitching.

- Additional Reinforcement for Crack Repair.

- Drilling and Plugging Method.

- Gravity Filling Method.

- Grouting Method of Crack Repair.

- Overlay and Surface Treatments of Cracks.

Grooving and Sealing Method

In this method the crack is enlarged along its exposed face to form a V-shaped groove up to a minimum width of 6 mm and a depth of 6 to 25 mm. The groove thus formed is filled and sealed with suitable material. For relatively lower performance of repair but to get quicker work, the routing operation can be omitted.

Flexible Concrete Crack Filler

Polyurethane-Based Crack Sealants: Polyurethane crack sealants are known for their flexibility and durability. They can effectively fill and seal cracks while remaining flexible to accommodate minor movements in the concrete. Polyurethane-based fillers are resistant to moisture, chemicals, and UV exposure, making them suitable for both interior and exterior applications.

Crack Repair

Epoxy Injection: Epoxy injection is a widely used method for repairing cracks in concrete. It involves injecting epoxy resin into the crack, which fills and seals the void. Epoxy injection is effective for both structural and non-structural cracks and provides excellent bonding strength. It can be used for horizontal, vertical, and overhead cracks.

Slab Crack Repair

Concrete Crack Filler: For small, hairline cracks, a concrete crack filler can be used. These fillers come in various forms, such as liquid sealants, caulks, or concrete patching compounds. The crack is cleaned, and the filler is applied, either by pouring it directly into the crack or using a caulking gun. The filler is then smoothed and leveled with a trowel or putty knife.

Concrete Crack Patch

Preparation: Start by cleaning the crack thoroughly to remove any loose debris, dust, or contaminants. You can use a wire brush, compressed air, or a high-pressure washer to ensure a clean and debris-free surface.

Like this post? Share it with your friends!

Suggested Read –

- Exterior Concrete Finishes

- Procedure for Rcc Concrete

- Top 15+ Best Plywood Brands in India

- Live Load Vs Dead Load | What Is Load in Civil

- What Is Composite Masonry | Type of Composite Masonry

- Precipitation | Type of Precipitation | Cyclonic Precipitation

- M30 Grade of Concrete Mix Design Procedure with OPC 53 Cement

- What Is Consistency of Cement | What Is Initial Setting Time of Cement | What Is Final Setting Time of Cement

- What Is the Gradient of Road | 6 Types of Road Gradient | Factors Affecting Gradient |Effect of Gradient on Roads

- What Is Window | 14 Different Types of Window | Functions of Windows | Location of Windows | Standard Height of Windows

Leave a Reply