Introduction of Hydraulic Cement

Important Point

Water is the biggest enemy of the Civil Engineering Structures. Water can cause great damage to the structures. It is very necessary to protect the structures from moisture which can cause huge damage to the structures.

The other types of cement cannot be used for the construction of the structures which are in contact with water. If we construct the underwater structures with the normal cement then it will undergo corrosion and get damaged.

But you might think that there are many civil engineering structures are constructed like bridges, dams which are in constant contact with water. So how it is possible to built the structures in the water?

There is a special type of cement, known as hydraulic cement, or hydraulic concrete, which is used for the construction of structures that remain in contact with water.

In this article, you will get to know all about the Hydraulic cement and the Hydraulic cement applications.

Also, Read: 10 Best Cement Companies In India

What Is Hydraulic Cement?

Hydraulic cement is a special type of cement which sets quickly and get hardened with the addition of water to the finely ground cement is known as the Hydraulic Cement.

In ancient times, the hydraulic cement was firstly used by the Romans. Hydraulic cement is best suitable for the structures which are constantly in the contact with water.

Hydraulic cement is nowadays widely used in the Construction Industry because it is non-shrinkable, non-corrosive and non-rusting.

Hydraulic cement has the ability to react with water under ambient conditions to form a hardened and water-resistant product. Different blends of modern Portland cement are commercially referred to as the Hydraulic Cement.

Hydraulic cement is a product which generally used to stop water and sets quickly when exposed to the water. Hydraulic cement sets within 5-10 minutes after adding water to it.

It is a type of cement which is similar to the mortar. Hydraulic cement is widely used in the Construction Industry for sealing the structures below grade and in the conditions where structures are submerged in water.

Also, Read: How Cement is Made | Cement Ingredients | History of Cement

Useful Article for You

- What Is Composite Wood

- What Is the Difference Between a Shower Pan and a Shower Base?

- What Is Raft

- What Is a Window Panel

- What Is Rebar Made Of

- What Is Crane

- What Is a Frame Structure

- What Is the Measurement for a Queen Size Bed

- What Is Considered Livable Space

- What Is One Way You Can Save Electricity?

- What Is Mdf Mean

- What Is a Bundle of Shingles

- What Is a Gallon of Water Weigh

- What Is Window Sash

- Cantilever Bridge Disadvantages

- What Is a Sieve Analysis

- What Is the Little Black Diamond on a Tape Measure

- What Is the Difference Between a Bolt and a Screw?

- What Is Overhang

- What Is Sand Blasting

- What Is a Walk in Basement

Chemical Composition of Hydraulic Cement

There are mainly four components of the hydraulic Cement

- Belite (2CaO·SiO2)

- Alite (3CaO·SiO2)

- Tricalcium aluminate/ Celite (3CaO·Al2O3)

- Brownmillerite (4CaO·Al2O3Fe2O3)

The mechanical properties of the hydraulic cement are given by the silicates.

Some additives are also needed for special properties such as greatly reduced setting and curing time, prevention of shrinking, being able to be used underwater etc.

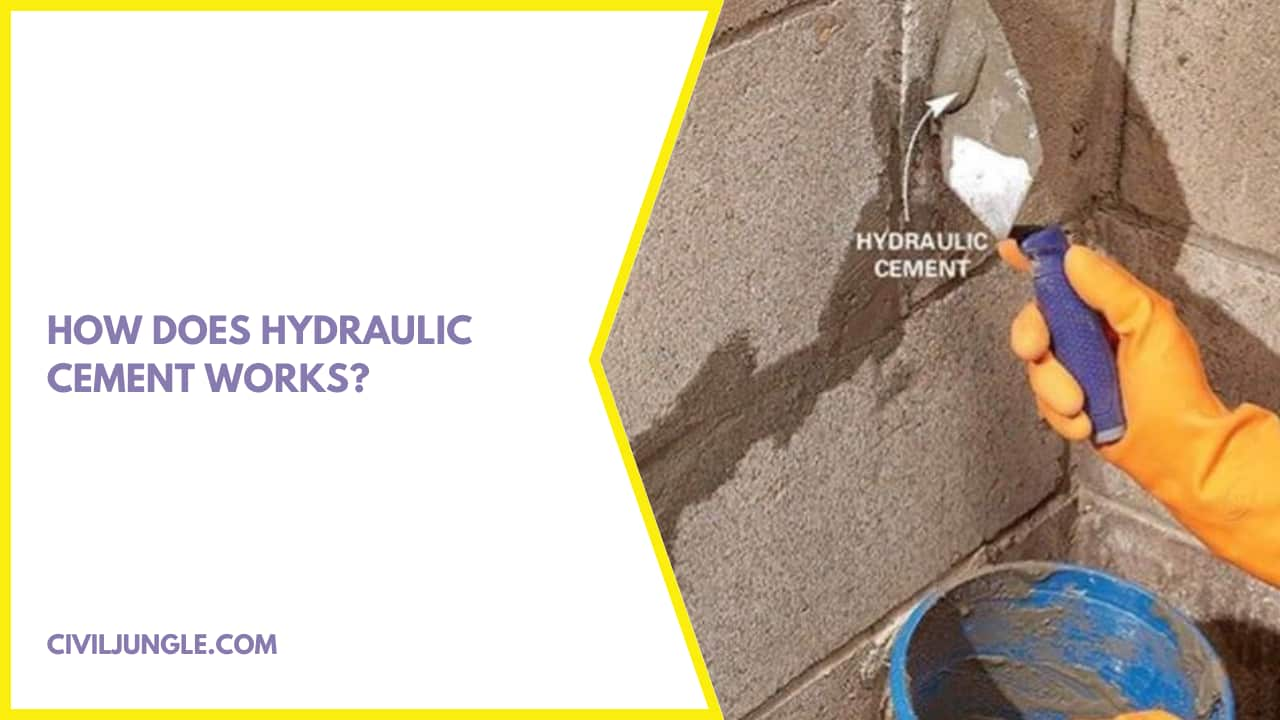

How Does Hydraulic Cement Works?

How to use hydraulic cement involves understanding that it works on the principle of the process of hydration. It means that dry hydraulic cement gets hardened when it is exposed to the water.

The nature of the chemical products which are used in hydraulic cement makes it impervious to the water damages and chemical attacks.

That’s why Hydraulic cement is widely used in the construction of the structures which are in contact with water.

The main products in the hydraulic cement are calcium silicate hydrate which increases the strength of the structures and make it watertight.

Also, Read: Density of Cement Sand and Aggregate | Cement Density | Sand Density | Aggregate Density | list of Density

Suitability of Hydraulic Cement for Construction

- It is important to select the right type of cement as per the nature of the Construction work.

- Hydraulic cement is suitable for the construction projects which required a fast setting and less curing time. Such types of projects give less time to work.

- It is recommended to use hydraulic cement only for the construction works which can be constructed within 10-15 minutes with a moderate amount of cement mix.

- Hydraulic cement has the ability to provide strength for the structures which are in the contact with water. This cement is used for the construction of highly durable structures.

- It is important to taken proper measures while applying the hydraulic cement in the cold climates.

- Hydraulic cement does not shrink like normal cement, and some types even expand while hardening, which is useful for sealing and repair works. This type of hydraulic cement which has the property to expand is very useful for the sealing and repair works.

- Repairing concrete structures with Hydraulic cement is very durable and holds for many years.

Also, Read: 23 Different Types Cements Available in India and As Per IS Standards

Hydraulic Cement Uses

When using hydraulic cement, it is widely employed for the construction of various structures. which are listed are as follows

- Swimming pools

- Foundations

- Elevator pits

- Drainage systems

- Basement walls

- Manholes

- Chimneys

- Cisterns and fountains

- Marine Applications

- For sealing the concrete and masonry structures

Hydraulic Cement Applications in Repairing Work for Civil Engineering Structures.

- Hydraulic cement grouting is also one of the commonly used methods for repairing cracks in concrete.

- Hydraulic cement is used for repairing of dormant cracks in the concrete.

- Hydraulic cement is widely used for the special Repairing work which includes.

- The repairing of the foundation.

- Repair of the cracks in the basement.

- Repairing of concrete walls, floors and driveways.

- Hydraulic cement is also used for sealing and repairing masonry as well as concrete structures.

Also, Read: What Is Water Cement Ratio | Water-Cement Ratio and Concrete Strength | Role of Water in Concrete

Useful Article for You

- What Is Quarrying

- What Is a Concrete Slump Test

- What Is a Weir

- What Is Road Made Of

- What Is a Cantilever?

- What Is a Contour

- What Is a Rolled Curb

- What Is an Abutment Bridge

- Gray Green House

- Identify the Zero-Force Members in the Truss

- Bridge Pier

- Monolithic Concrete

- Wall Panel Bathroom Ideas

- Construction Companies in America

- How Bridges Are Made

- Density of Concrete G Cm3

- Concrete Wall Treatment

- Standard Us Brick Size

- Drywall Ceiling Repair Cost

- Micropile

How to Apply Hydraulic Cement?

- First point clean the surface where the hydraulic cement has to be applied.

- The surface should be free from Oil dirt or any other contaminant otherwise there should not be proper Bond will be formed.

- The area where hydraulic cement to be applied should be saturated for 24 hours before its application.

- To how to mix hydraulic cement, it should be blended with a mechanical mixture to form a uniform mix.

- Add water in it as per the manufacturer’s recommendation.

- If there is excess water remove it otherwise there will be difficulty in its application.

- Apply the hydraulic cement wherever required.

Advantages of Hydraulic Cement

- One of the advantages of hydraulic cement, or hydro cement, is that it is easy to work and apply.

- Hydraulic cement quickly sets and hardened which will help to achieve the desired strength quickly.

- Hydraulic cement is non-shrinkable and does not undergo corrosion.

- Hydraulic Cement is waterproof and can be used for the construction of underwater structures.

- Hydraulic cement is an economical solution compared to other cement products.

- Hydraulic cement is widely used for the construction of durable concrete repair works.

- Hydraulic cement can be used for sealing of the basement and other concrete leakages.

Also, Read: Grades of Cement | Types of Cement Grades | Which Grade Cement Is Used for Slab

Disadvantages of Hydraulic Cement

- One disadvantage of hydraulic cement, or hydrolic cement, is that it hardens very quickly, making it necessary to use within 10 to 15 minutes of mixing.

- The Hydraulic cement cannot be used for the frozen surfaces.

- Hydraulic cement is not flexible only suitable for providing mechanical support.

- Hydraulic cement cannot be used for the areas where the is below 48°F.

Hydraulic Cement Applications

Hydraulic cement can be used above of below-grade, however, it is extremely useful if used in:

- Swimming Pools

- Drainage systems

- Foundations

- Elevator pits

- Basement walls

- Manholes

- Sealing around concrete and masonry structures

- Marine applications.

- Chimneys

- Cisterns and fountains.

Is Hydraulic Cement Waterproof?

A non-shrink, high-strength waterproof mortar for concrete, masonry, brick, stone and stucco. Mix with water into a putty consistency. Sets in 3-5 minutes to stop active water leaks and seepage under pressure through holes, cracks, wall-floor joints, swimming pools, water storage tanks, fountains, ponds, and drains.

Expansive Hydraulic Cement

A cement that when mixed with water produces a paste that after setting increases in volume to a greater degree than does portland-cement paste. Expansive concretes are divided into two categories, shrinkage-compensating, and self-stressing.

Expanding Hydraulic Cement

ChemPlug is a fast-setting, expansive hydraulic cement and is compounded to withstand continual exposure to water, even under pressure. It is cement based, fills and seals the pores and voids of the concrete or masonry surface.

Hydraulic Cement Uses

- Swimming Pools

- Drainage systems

- Foundations

- Elevator pits

- Basement walls

- Manholes

- Sealing around concrete and masonry structures

- Marine applications.

- Chimneys

- Cisterns and fountains

What Is Hydraulic Cement Used For?

Hydraulic Cement is a blend of hydraulic cement and proprietary admixtures used for plugging and stopping water or fluid leaks in concrete structures and masonry walls. When mixed to a thick consistency and hand-formed, Hydraulic Cement will set in 3-5 minutes to seal out water.

Hydraulic Cement to Fill Cracks

Hydraulic Cement Disappointed, the homeowner will remove the caulk, chisel out the crack, and fill it with hydraulic cement. However, hydraulic cement has a weak bond with concrete, which is the reason the crack needs an inverted V-groove to hold it in.

How to Mixing Hydraulic Cement?

Blend 4 – 4 1/2 parts Water-Stop Cement to 1 part water, by weight. Ingredients should be mixed to form a heavy putty consistency. Do not mix more material than can be used in 2 – 3 minutes. In most cases, limit batch size to 4 – 6 oz (113 – 170 g) of powder.

Best Hydraulic Cement

Here, the best hydraulic cement companies are as follows.

- Quikrete

- Rapid Set

- Drylok

- Sakrete

- Krystol

- Zinsser

- Rutland

Like this post? Share it with your friends!

Suggested Read –

- Biggest Roofing Companies in Usa

- Difference Between CPM and PERT | What Is CPM & PERT

- Top 10 Companies for Environmental Engineers to Work For

- Difference Between One Way Slab and Two Way Slab | What is Slab

- What Are Planted Column, Floating Column, Hanging Column, and Stub Column

- Meaning | What Is Waterlogging | How to Prevent Waterlogging | Effect of Waterlogging

- What Is Mix Design of Concrete | Nominal Mix | Design Mix| Difference Between Nominal Mix

- What Is Reinforced Brick Masonry | Construction of the Reinforced Brick wall | What Is Reinforced Brick

Leave a Reply